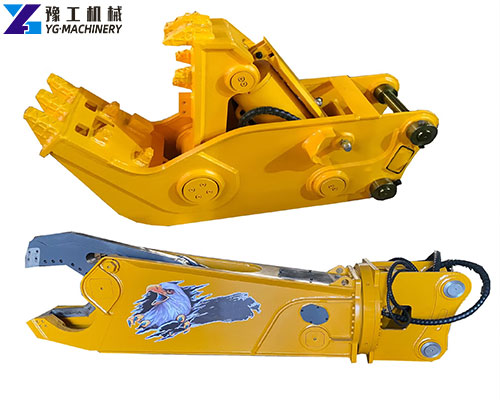

In the field of engineering demolition and waste recycling, efficiency and cost are the keys to success. The YG excavator eagle shear is a high-performance hydraulic shear designed for excavators, designed to completely change the way you do crushing work. This powerful attachment helps you easily deal with all kinds of hard materials with its excellent shearing force, extraordinary durability, and efficient working ability. Whether it is dealing with reinforced concrete or shearing thick and heavy metal, YG excavator eagle shear can provide accurate and fast solutions, significantly improve your work efficiency, and effectively reduce operating costs. Choose the YG excavator eagle shear and contact us now to obtain product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Excavator Eagle Shear Parameter

| Product | Excavator-mounted hydraulic demolition shear for waste scrap rebar | ||||

| Item | YG-620 | YG-1413 | YG-2200 | YG-2977 | YG-4052 |

| Weight kg | 620 | 1413 | 2200 | 2977 | 4052 |

| Max. Open Size mm | 334.4 | 540 | 500 | 660 | 801 |

| Width mm | 864 | 1175 | 1370 | 1600 | 1700 |

| Height mm | 1521 | 2050 | 2380 | 2600 | 2700 |

| Effective Shear Depth mm | 286 | 348 | 486 | 578 | 736 |

| Rotating Way | 360 collision | 360 hydraulic | |||

| Working Pressure Bar | 235 | 300 | 320 | 320 | 320 |

| Bottom Shear Force T | 81.2 | 138.2 | 171.2 | 330.2 | 387.2 |

| Medium Shear Force T | 50.2 | 80.2 | 100.2 | 189.2 | 218.2 |

| Tip Shear Force T | 32.2 | 53.2 | 75.2 | 127.2 | 147.2 |

| Applied Excavator Weight T | 5-9 | 10-19 | 20-25 | 28-35 | 38-50 |

Working Principle of the Excavator Eagle Shear

YG excavator eagle shear is mainly driven by hydraulic power provided by the excavator. The hydraulic oil enters the shear cylinder through the hydraulic pipeline, pushing the piston to move, driving the shear blade to open and close, thereby shearing the material. The high-strength blade and optimized mechanical structure design ensure a strong shearing force and a reliable shearing effect. For models equipped with a rotating mechanism, the hydraulic motor drives the rotating gear to achieve 360-degree rotation of the shear head, which is convenient for operation at different angles.

What Are the Traditional Ways of Breaking?

- Manual demolition/breaking: Breaking small structures or non-load-bearing structures by hitting and prying them with tools such as sledgehammers and chisels.

- Breaker (hydraulic breaker/cannon hammer): Breaking concrete, rocks, etc., using impact force. The breaker is driven by the hydraulic system of the excavator, but its working principle is impact rather than shearing.

- Blasting demolition: In the demolition of large, solid structures, the shock wave generated by the explosion is used to break the structure through the precise calculation and arrangement of explosives.

- Spherical breaking/heavy object falling: Using the impact force generated by heavy objects (such as steel balls) falling from a height to break ground structures or deposits.

- Flame cutting: Mainly used for metal structures, melting and cutting metals through high-temperature flames.

Why Are More and More Customers Choosing Hydraulic Shears for Excavator Attachments?

- Efficiency and versatility: Excavator hydraulic shears can quickly and accurately shear and crush all kinds of hard materials, such as reinforced concrete, scrap metal, wood, etc. By simply replacing different shear jaws, it can adapt to a variety of crushing needs, realize multi-purpose use of one machine, and greatly improve equipment utilization and operating efficiency.

- Improved safety: Compared with traditional manual or blasting crushing, hydraulic shearing operations are operated by the excavator driver in a safe cab, avoiding direct contact between personnel and crushed materials, greatly reducing the risk of accidents at the construction site. In addition, the splashes and dust generated by hydraulic shearing operations are relatively small, which improves the working environment.

- Better environmental protection: The noise and vibration generated during the crushing process of hydraulic shears are much lower than those of traditional breaker hammers or blasting, reducing the impact on the surrounding environment and residents. At the same time, precise shearing helps to classify and recycle different materials and promote resource recycling, which meets the increasingly stringent requirements of today’s society for environmental protection.

- High operational flexibility: Excavators have excellent mobility. As an accessory, hydraulic shears can be easily moved to different work sites with the excavator, adapting to various complex terrains and narrow spaces, which is difficult to match with fixed crushing equipment.

- Reduced operating costs: Although the initial investment may be relatively high, the high efficiency and low maintenance requirements of hydraulic shears (compared to the frequent replacement of the drill rod of traditional breaker hammers) can significantly reduce long-term operating costs. In addition, its precise crushing ability reduces the cost of secondary sorting and transportation.

- Wide range of applications: Whether it is building demolition, waste recycling, steel mill scrap processing, or emergency rescue, hydraulic shears can play an important role and meet the professional needs of customers in different industries.

Customer Usage and Evaluation of Hydraulic Shears for Excavator Attachments

Case 1: A scrap metal recycling company in the United States

The company is a large scrap metal recycling company that has been facing the problem of handling large amounts of scrap steel. After introducing the YG excavator eagle shear, its scrap steel processing efficiency has been greatly improved, and the daily processing volume has increased by more than 50%. Customer feedback: YG’s excavator shears are powerful, and the blades are very durable. They can maintain good performance even after long-term high-intensity work, which greatly reduces their operating costs.

Case 2: A building demolition team in Australia

The team used YG’s excavator eagle shear in a steel structure factory demolition project. The customer said that the equipment has a very fast cutting speed and can easily cut through thick steel beams and columns, greatly shortening the demolition period. It is also very convenient and safe to operate, which has won unanimous praise from its operators.

Excavator Eagle Shear Price & Purchase Information

The price of the YG excavator eagle shear will fluctuate according to the model, specification, configuration, and market supply and demand. Generally speaking, the prices of excavator hydraulic shears with different shearing capacities and functions will vary. We provide a variety of models of excavator shear attachments to meet the needs of different customers. As a factory-direct sales, YG can provide you with more competitive prices and more complete after-sales service guarantees. If you are interested in the YG excavator eagle shear, please contact us now to get detailed product quotes and technical parameters.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()