The tyre shredding machine is mechanical equipment specialized in shredding waste tires. It uses the shearing principle to shred the entire waste tire into small rubber pieces for later reuse or direct use. Tire shredder is an environmentally friendly waste recycling and shredding equipment independently developed and designed by our factory technicians based on the introduction and absorption of foreign advanced technology and years of manufacturing experience. It has the advantages of uniform discharge, high shredding efficiency, large output, and reliable performance, and scrap tire shredder is the shredding device in waste tire recycling lines, and can be widely used in the waste recycling industry. 【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Tyre Shredding Machine Parameter:

| Model | YG-600 | YG-1000 | YG-1200 | YG-1500 | YG-1800 |

| Knife size(mm) |

Φ200*20 | Φ300*30 | Φ300*40 | Φ500*50 | Φ600*60 |

| Power (kW) | 11*2 | 37*2 | 45*2 | 75*2 | 90*2 |

| Capacity(t/h) | 0.3-0.5 | 1-1.2 | 2.5-3 | 3.8-4.5 | 6-7 |

| Knife quantity(pcs) |

30 | 26 | 30 | 38 | 45 |

| Machine size(m) |

2.6*1*2.1 | 3.4*1.25*2.2 | 3.8*1.25*2.2 | 4.4*1.5*2.5 | 5.3*2.1*2.8 |

What Kinds of Tyres and Rubber Can Be Shredded?

Many kinds of tyre waste and rubbers can be recycled by tire shredder. The majority of tyres and rubbers can be shredded.

Tires are found on cars, trucks, buses, forklifts, strollers, shopping carts, wheelchairs, bicycles, motorcycles, aircraft landing gear, tractors and other ship construction, agricultural machine building, railroad transport, and construction fields.

The rubber is found on mats, bathing caps, inflatable inner tubes, rubber rings, gloves, pacifier mattresses, shoe soles, hot water bottles, balloons, rubber boots, seal rings, mulch, sports turf, rubber thread, foam-rubber seats for automobiles and furniture.

Application Fields of Shredded Tires:

- Sports ground patching: running tracks, school sports grounds, swimming pools around and garden paths, bowling greens, sidewalks, kindergarten sports grounds and playgrounds, tennis and basketball courts.

- Automotive industry: floor mats for trains, flooring for cars and trucks, marine daily materials, tires, and tire pads.

- Construction equipment: adhesives/sealants, hospitals, companies, bathroom floors, insulation materials, coatings, dams, warehouses, ponds, waste treatment stations, house signs, sheets, waterproofing materials, shockproofing, coils, waterproofing materials for roofs and walls.

- Production of recycled rubber amines: used in the production of various rubber systems.

6 Features of Tyre Shredding Machine:

- Heavy moving blade, high crushing efficiency, the blades are cast with alloy steel, strong and long service life.

- The thick frame plate can resist high torque and is very strong.

- It adopts microcomputer (PLC) automatic control, with start, stop, reverse, and overload automatic reverse control functions.

- The equipment has the characteristics of low speed, high torque, low noise, and dust that can meet environmental protection standards.

- Easy to adjust, low maintenance cost, economical, and durable.

- The thickness of the blade and the number of claws can be replaced according to different materials.

Why Need a Waste Tire Shredder?

- Tires are very strong, and it is difficult for ordinary machinery to shred them. Some people rely on the purchase of expensive or high-power and low-efficiency equipment, and the investment cost is too high; some cut waste tires by hand and then shred them.

- The recycling efficiency is extremely low, and it is time-consuming and labor-intensive. How to utilize waste tires in large quantities economically and effectively has become a topic of rubber recycling.

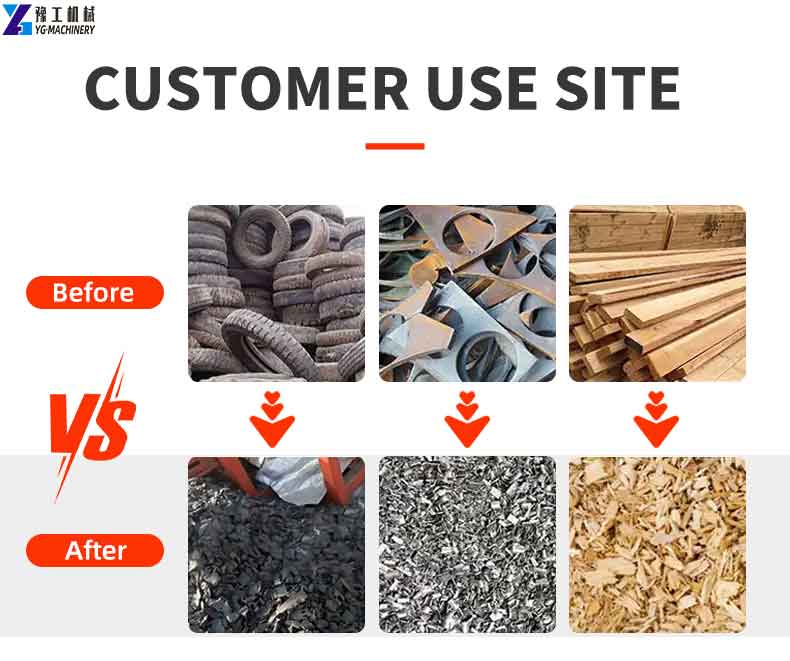

- To meet market demands, we have specially developed a waste tire shredder for handling various waste bulky objects such as used tires, waste plastic barrels, scrap metals, waste wood, etc., which are convenient for further processing.

- After the tires are shredded, they can be ground into a rubber powder through milling equipment for reprocessing and recycling. This scrap tire shredder not only reduces environmental pollution but also brings economic benefits.

- The rubber tyre shredder is easy to operate as it only needs to throw the whole tire directly into it, and tires can be shredded into small pieces and come out, which is very convenient and reduces labor.

Buy the Tyre Shredding Machine from YG Machinery

With the rapid development of automobiles, raw rubber has become increasingly scarce in recent years. How to effectively use scrap tires has become a problem to be solved by humans around the world. Some rely on purchasing expensive or high-power and low-efficiency equipment, which has too high an investment cost. Some manually saw the scrap tires into small pieces and then crushed them, which has extremely low recycling efficiency. How to economically and effectively use waste tires in large quantities has become a key topic for rubber. After several years of concentration and learning from the advanced experience of similar foreign products, we have successfully developed a large-scale fully automatic shredding unit through continuous improvement.

As a professional shredder manufacturer and supplier, we also have tire recycling lines, scrap metal recycling lines, plastic recycling lines, wood recycling lines, wood shredder machines, firewood splitter machines, etc. We also have a series of packaging equipment. If you want to invest in this industry, please get in touch with us.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

FAQ:

Q: When we establish one kind of shredder machine, can we use it to shred other materials?

A: Yes, you can. We will design the shredder machine for you as per your materials.

Q: How to choose a suitable shredder?

A: Please tell us your raw material and what capacity you need, and we will recommend you the most suitable shredder.

Q: What about the machine installation?

A: For the waste tire shredder machine installation, we will provide you with the wire connection drawing and technical support, normally you can finish by yourself; But if you need our technician, we will send a technician to your working site as required.

Q: How about the spare parts?

A: We permanently provide spare parts at a cost price and will give you the spare parts list when you purchase the machine.

Q: Will you test the shredder machine before delivery?

A: We will test every machine and production line before delivery and send you the working video. You also can come to us for an inspection before delivery.