Before the water well drilling rigs are used for engineering, there are usually 60 hours of the running-in period according to general regulations which are based on the initial technical characteristics of the water well drilling machine. If the water drilling machine is overused for a long time during the run-in period, it will lead to frequent machine failures affect the normal operation of the machine, and shorten the service life. So users must pay more attention to the proper use of drilling machines during the run-in period.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

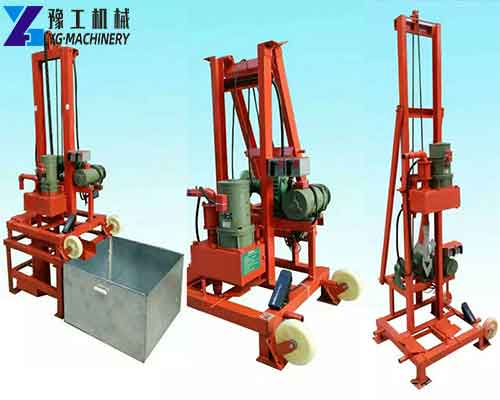

YG Water Well Drilling Rigs Series

Characteristics of Water Well Drilling Rigs During Run-in Period:

- Quick wear. Due to the influence of processing, assembly, and adjustment of new drill rig machines, the friction surface is rough, the matching surface has a small contact area, and the pressure on the surface is uneven. All the aspects accelerate the wear of the fitting surface of the part.

- Bad lubrication. The fitting clearance of newly assembled parts is small, which can’t guarantee the evenness of the fitting clearance. Lubricating oil isn’t easy to form a uniform oil film on the friction surface, which can reduce the lubrication efficiency and cause the early abnormal wear of the machine.

- Easy to lose. Under the influence of factors such as heat, deformation, and the reasons for too fast wear, the new processes and assembled parts are easy to cause the loss of the originally tightened parts.

- Leakages occur. Because of the loose parts, vibration, and the influence of heat on the machine, leakage may occur on the sealing surface of the drilling equipment and on the pipe joint.

Operation And Maintenance of Well Drilling Rigs During Run-in Period:

- Operators should receive training and guidance to fully understand the structure and performance of the rigs. Before operating the machine, be sure to read the operation and maintenance manual first and operate and maintain the machine according to the instructions.

- Pay attention to the workload of the run-in period. Generally, the working load during the run-in period should not exceed 80% of the rated working load, and it is also necessary to prevent overheating caused by the long continuous operation of the machine.

- Always observe the instructions on each instrument. If there is any normal situation, please stop the machine immediately and check the causes of the breakdown. The operation should be stopped before troubleshooting.

- The hydraulic water well drilling rig machine should be lubricated before working. For that, dirty water containing sediment can easily enter the machine, which will wear down the bearing and reduce the sensitivity of the rig’s lifter. Please keep the rigs clean, adjust, and tighten the loose parts in time to prevent them from wearing or losing.

- Always check the lubricating oil, hydraulic oil, coolant, brake fluid, and duel oil or water, as well as check the sealing of the whole well rig machine.

- After the end of the run-in period, the machine should be forced maintenance, check and adjust the machine, and change the oil at the same time.

- Check for cracks, corrosion, unsoldering, and other damage to the steel structure.

- Check whether the main and auxiliary steel wire rope is broken and if its connection is intact and safe.