Our Mexican customer, who closed a deal last week, has a poultry farm. Due to the increasing number of poultry, egg production is also increasing. Therefore, new equipment is urgently needed to ensure basic packaging solutions. The customer currently uses manual drying, the raw materials are not environmentally friendly, and more labor is required. Our machine can be matched with a variety of solutions. The egg tray making machine is fully automatic and easy to operate, so the customer liked our solution very much, and soon paid and started cooperating. Do you want to know the egg tray making machine price? Contact us now!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Egg Tray Making Machine Parameter:

| Model | YG-1*3 | YG-1*4 | YG-3*4 | YG-4*4 | YG-4*8 | YG-5*8 | YG-6*8 |

| Capacity (pcs/h) | 1000 | 1500 | 2500 | 3500 | 4500 | 5500 | 7000 |

| Forming Mould Quantity | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Total Power (kW) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Electricity Consumption (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Worker | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

Current Problems of the Mexico Customer:

- Currently, the customer’s packaging materials are expensive and need to be replaced frequently.

- The manual packaging process takes a long time and requires a large number of workers.

- Traditional packaging materials are not biodegradable, causing environmental pollution and failing to meet environmental standards.

- The available packaging options are limited, unable to meet the customer’s specific brand needs, and do not support customization.

Customized Solutions:

- The customer purchases an egg tray machine and produces egg trays by themselves, making packaging more convenient.

- The fully automatic paper egg tray machine sold by Yugong Machinery can produce many egg trays quickly, thereby reducing labor costs.

- Recycled pulp, which is both environmentally friendly and biodegradable, can be used as the raw materials for egg trays.

- The customized machine can produce egg trays of various sizes and designs, allowing customers to create customized packaging that matches their brand and meets more customer needs.

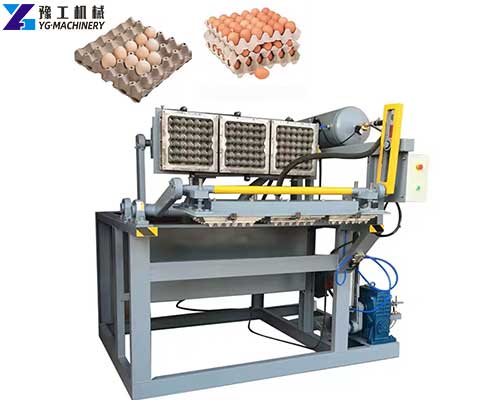

Check YG Egg Tray Making Machine Features:

- High efficiency: From pulping of raw materials to egg tray molding, the entire production process of our egg tray machine production line is highly automated, and according to different models, the production capacity of the egg tray machine is 1000-7000pcs per hour, which improves production efficiency and meets the needs of large-scale production.

- Environmental protection: The egg tray machine can use waste paper, cardboard, and other waste as raw materials, and the egg tray products produced are biodegradable and environmentally friendly.

- A variety of products: By changing the mold, the egg tray machine can produce egg trays of various specifications and shapes to meet the needs of different customers.

- Simple operation: The equipment is equipped with a PLC control system, which is simple to operate, easy to master, and convenient to maintain.

- Wide application: It can be used for packaging eggs, fruits, shoe trays, precision instruments, electronic products, and various fragile products.

Egg Tray Making Machine Price – YG Machinery Manufacturer

As a professional egg carton machine manufacturer, we are committed to providing customers with high-quality and efficient egg tray production solutions. Egg tray machines are reasonably priced and have stable performance. We not only offer standardized egg tray machines but also customize egg tray machines of various specifications according to customers’ needs. At the same time, we provide comprehensive after-sales service to ensure the stable operation of the equipment and provide customers with all-around protection. Want to start your business? Contact us now!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800