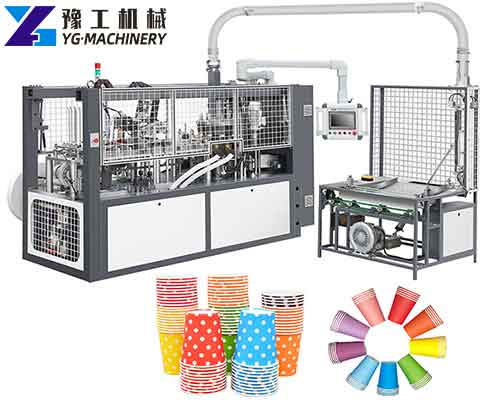

The disposable cup-making machine is a kind of paper container made of base paper (white cardboard) made of chemical wood pulp for mechanical processing and bonding. It has a cup-shaped appearance and can be used for frozen food and hot drinks. It has the characteristics of safety, hygiene, lightweight, and convenience, and is the ideal equipment for public places, and restaurants.

Everyone should know that disposable paper cups are very necessary for our lives, and their daily consumption is very high. It can be seen that the market demand is very large, and the technology for producing disposable paper cups is simple, mainly by paper cup-forming machines. The paper cup forming machine is a multi-station automatic forming machine, which can produce various paper cups through continuous processes such as automatic paper feeding, sealing, and knurling. YG Machinery’s paper production equipment has always been the industry leader, such as paper cup printing machines, roll die cutting machines, double wall paper cup machines, folder gluer machines, paper bowl machines, paper dish making machines, paper straw making machines, paper carton erecting machines, and so on.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Parameter of Automatic Paper Cup Machine:

| Model | YG-800 | YG-C800 | YG-S800 | |

| Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

| Raw Material | One-side PE | One-side PE | One-side or two-side PE-coated paper (Singe PE or Double PE coated paper) |

|

| Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

| Suitable paper weight | 150-180g;±20g | 150-300g;±20g | 160-300g/;±20g | |

| Voltage supply | 380V, 50HZ | 380V, 50HZ | 380V(220V) 50HZ | |

| cup size | Bottom35-70mm, Top45-90mm High32-135mm |

Bottom35-70mm,Top45-90mm, High32-135mm |

Bottom35-70mm, Top45-90mm, High32-135mm |

|

| General power | 4.5 kW | 5 kW | 6 kW | |

| Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m3/min | |

| Net weight | 1680kg | 1680kg | 2000kg | |

| Measurement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

| Cup holder | L:900mm;W:600mm;H:1500mm | |||

| Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

| Bottom Knurling | Heating | Heating | Hot Air System | |

|

We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. |

||||

Paper Cup Classification:

Paper cups are divided into single-sided PE-coated paper cups and double-sided PE-coated paper cups:

Single-sided PE-coated paper cups: Paper cups produced with single-sided PE-coated paper are called single PE paper cups (the common market paper cups in China, most of the advertising paper cups are single-sided PE-coated paper cups), and their manifestations are: paper cups filled with water There is a smooth PE coating on the side.

Double-sided PE-coated paper cups: Paper cups produced with double-sided PE-coated paper are called double-sided PE paper cups, expressed in the form of PE coating on the inside and outside of the paper cup (mostly used for cold cups).

Paper cup size: We use ounces (OZ) to measure the size of paper cups. For example, 8 ounces, 12 ounces, and 16 ounces of paper cups, etc. are commonly found in the market.

Ounce (OZ): An ounce is a unit of weight, which is represented here: The weight of 1 ounce is equivalent to the weight of 28.34 milliliters of water, which can be expressed as follows: 1 ounce (OZ) = 28.34 milliliters (ml) = 28.34 grams (g).

Application of YG Disposable Cup-Making Machine:

Paper cups used for frozen foods are coated with wax, which can hold ice cream, jam, butter, etc. The paper cups used for hot drinks are coated with plastic, which can withstand temperatures above 90°C and bloom with water. The characteristics of paper cups are safety, sanitation, lightness, and convenience. It can be used in public places, restaurants, and restaurants. It is a disposable item.

The Performance Characteristics of the Paper Cup Machine:

The paper cup has a mouth-shaped appearance and can be used for frozen food and hot drinks. It has the characteristics of safety, health, lightness, and convenience.

- Lightweight and anti-breakage. Compared with glass bottle cups, paper cups are lighter and have no risk of damage.

- Low cost. Being lightweight can save circulation costs.

- Good appearance effect. Printing and decoration are easy to realize, with good publicity effect and promotion.

- It can be combined with a variety of materials to improve the protection function. It is compounded with aluminum foil, plastic, and other materials to prevent deterioration of the contents.

- Good shading performance can better maintain the color, fragrance, and taste of the contents.

- The packaging machinery can be used for operations to achieve high-quality and high-speed production and packaging.

- Easy to open and seal, easy to open, and easy to restore.

- It is easy to handle waste and easy to recycle, which can save resources.

- The emergence of new technologies and new processes has continuously improved the manufacturing technology of paper cups, and new types of paper cups will appear and play a greater role in promoting and promoting the variety of products.

Paper Cup Manufacturing Machine Price in YG Machinery:

Because paper cups are more environmentally friendly and cheaper than plastic cups, many people choose to buy paper cups, so the market for paper cups is wider. Disposable paper cup machines are also more popular. The price of a paper cup machine is also quite different, if you want to invest in a paper cup machine, please contact us. Also, you can check this page, how to start a paper cup production line. In addition, we also have shoe cover-making machines, surgical cap-making machines, disposable slipper machines, paper bag-making machines, woven bag lines, wet tissue machines, rewinders machines (wet wipe machines), tissue-making machines, etc. Contact us to know more.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800