Egg Tray Production Line Specification and Consumption:

| Production Line Models | Output (p/h) | Hydraulic Pulper | Egg Tray Machine | Drying Method | |||

| Natural Drying | Brick Drying Line | Single-layer Metal Drying Line | Multilayer Metal Drying Line | ||||

| YGDT3×1-1000 | 1000 | ZDS1(1m³) | DTF3×1 | √ | √ | √ | √ |

| YGDT4×1-1500 | 1500 | ZDS1(1m³) | DTF4×1 | √ | √ | √ | √ |

| YGDT3×4-2000 | 2000 | ZDS1(1m³) | DT3×4 | √ | √ | √ | √ |

| YGDT4×4-2500 | 2500 | ZDS2(2m³) | DT4×4 | √ | √ | √ | √ |

| YGDT3×8-3000 | 3000 | ZDS2(2m³) | DT3×8 | √ | √ | √ | |

| YGDT4×8-4000 | 4000 | ZDS4(4m³) | DT4×8 | √ | √ | √ | |

| YGDT5×8-5000 | 5000 | ZDS4(4m³) | DT5×8 | √ | √ | √ | |

| YGDT5×12-6000 | 6000 | ZDS6(6m³) | DT5×12 | √ | √ | √ | |

| YGDT6×8-7000 | 6000-7000 | ZDS6(6m³) | DT6×8 | √ | √ | √ | |

| Production Line Models | Drying Method | Raw Material(kg/h) | Power(kW/h) | Fuel Consumption | ||||

| Paper | Water | Coal(kg/h) | Gas(m³/h) | Diesel(kg/h) | LPG(kg/h) | |||

| YGDT3×1-1000 | Natural drying | 85 | 255 | 23.6 | ||||

| YGDT3×1-1000T | Brick drying line | 36.1 | 50 | 22-32 | 18-28 | 18-28 | ||

| YGDT3×1-1000J1 | Single-layer metal drying line | 36.1 | 22-32 | 18-28 | 18-28 | |||

| YGDT3×1-1000J6 | Multilayer metal drying line | 36.1 | 22-32 | 18-28 | 18-28 | |||

| YGDT4×1-1500 | Natural drying | 102 | 306 | 27.3 | ||||

| YGDT4×1-1500T | Brick drying line | 38.6 | 60 | 26-36 | 22-32 | 22-32 | ||

| YGDT4×1-1500J1 | Single-layer metal drying line | 38.6 | 26-36 | 22-32 | 22-32 | |||

| YGDT4×1-1500J6 | Multilayer metal drying line | 38.6 | 26-36 | 22-32 | 22-32 | |||

| YGDT3×4-2000 | Natural drying | 170 | 510 | 32.6 | ||||

| YGDT3×4-2000T | Brick drying line | 45.3 | 83 | 37-47 | 30-40 | 30-40 | ||

| YGDT3×4-2000J1 | Single-layer metal drying line | 45.3 | 37-47 | 30-40 | 30-40 | |||

| YGDT3×4-2000J6 | Multilayer metal drying line | 45.3 | 37-47 | 30-40 | 30-40 | |||

| YGDT4×4-2500 | Natural drying | 212 | 636 | 34.2 | ||||

| YGDT4×4-2500T | Brick drying line | 46.8 | 104 | 46-56 | 38-48 | 38-48 | ||

| YGDT4×4-2500J1 | Single-layer metal drying line | 46.8 | 46-56 | 38-48 | 38-48 | |||

| YGDT4×4-2500J6 | Multilayer metal drying line | 46.8 | 46-56 | 38-48 | 38-48 | |||

| YGDT3×8-3000T | Brick drying line | 255 | 765 | 88.9 | 125 | 56-66 | 46-56 | 46-56 |

| YGDT3×8-3000J1 | Single layer metal | 88.9 | 56-66 | 46-56 | 46-56 | |||

| YGDT3×8-3000J6 | Multilayer metal drying line | 88.9 | 56-66 | 46-56 | 46-56 | |||

| YGDT4×8-4000T | Brick drying line | 340 | 1020 | 91 | 160 | 67-77 | 55-65 | 55-65 |

| YGDT4×8-4000J1 | Single-layer metal drying line | 91 | 67-77 | 55-65 | 55-65 | |||

| YGDT4×8-4000J6 | Multilayer metal drying line | 91 | 67-77 | 55-65 | 55-65 | |||

| YGDT5×8-5000T | Brick drying line | 424 | 1272 | 100 | 185 | 82-92 | 67-77 | 67-77 |

| YGDT5×8-5000J1 | Single-layer metal drying line | 100 | 82-92 | 67-77 | 67-77 | |||

| YGDT5×8-5000J6 | Multilayer metal drying line | 100 | 82-92 | 67-77 | 67-77 | |||

| YGDT5×12-6000T | Brick drying line | 510 | 1530 | 105 | 208 | 92-103 | 77-87 | 77-87 |

| YGDT5×12-6000J1 | Single-layer metal drying line | 105 | 92-103 | 77-87 | 77-87 | |||

| YGDT5×12-6000J6 | Multilayer metal drying line | 105 | 92-103 | 77-87 | 77-87 | |||

Notes:

|

||||||||

Why Invest in the Egg Tray Production Line?

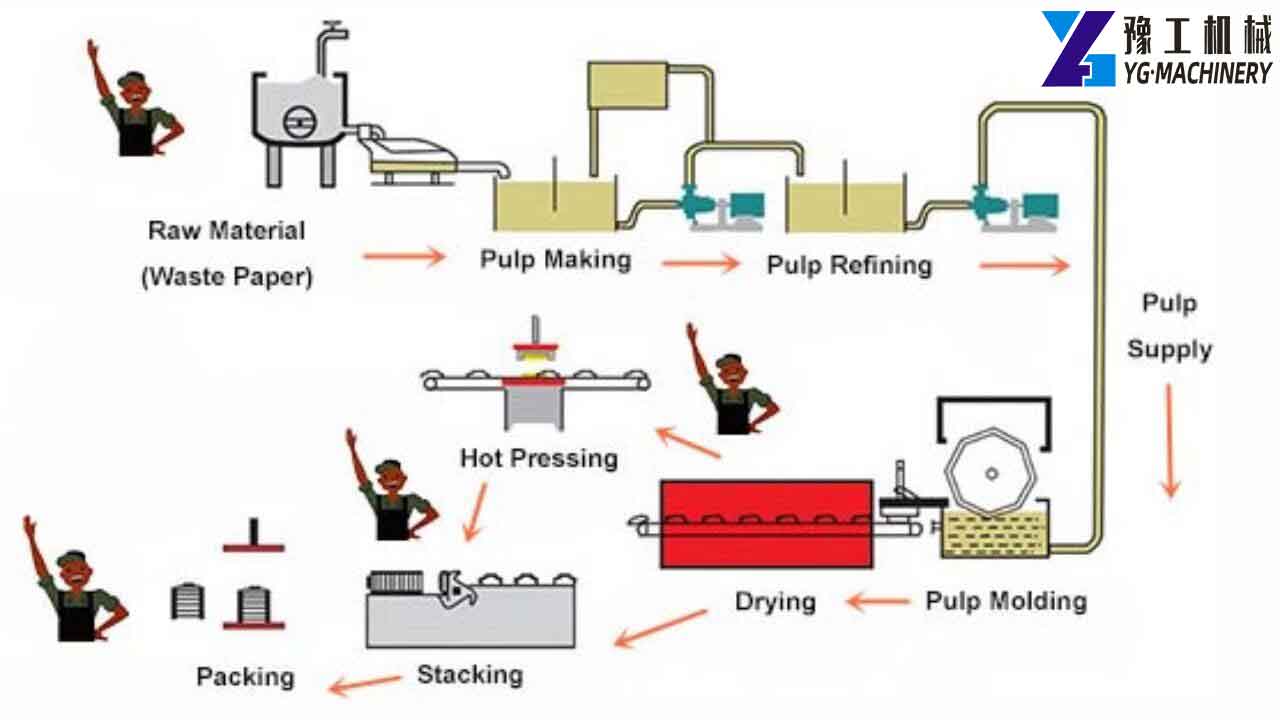

Wide Variety Of Raw Materials:

- Waste paper from printing houses.

- Ready-made plant fiber pulp and paper pulp.

- Discarded books and periodicals from publishing houses.

- Shredded document paper from enterprises and government agencies.

- Old newspapers, magazines, second-hand books, express cartons, and packaging boxes from family.

Broad Application Fields of Egg Tray:

- Waste paper recycling industry: This is an investment project with simple entry, low technical difficulty, low personnel demand, and high market return.

- Printing houses & paper mills: They can process the daily produced waste paper into egg trays through egg tray machines to realize a business expansion.

- Chicken farms, duck farms, and other livestock farms: Because of the large demand for egg trays, livestock farms can use egg tray machines to manufacture egg trays with low cost and high quality.

- Other investors: This is a business opportunity with broad prospects, high profits, small investment, low risk, and environmental protection.

Paper Egg Tray Making Machine Price – YG Machinery Manufacturer

The specific cost is affected by many factors such as the equipment model you need, the degree of machine automation, production capacity, the number of molds, the country of installation, and shipping costs. If you are interested in our paper egg tray-making machine, please contact us for a detailed quotation! We will provide the best solution according to your needs. In addition, we also have disposable cup-making machines, paper bag-making machines, tissue-making machines, wet wipes machines, garbage bag-making machines, woven bag-making machines, cast film machines, disposable slipper-making machines, shoe cover-making machines, surgical cap-making machines, etc. For further information or to get a quotation directly. Contact us now!