In applications such as metal rust removal, workpiece descaling, and surface roughening, many companies and technicians encounter difficulties with equipment adaptation, low efficiency, and complex operation. For example, after purchasing a separate sandblasting machine, they must also find a matching compressor, which frequently results in insufficient pressure and uneven blasting. Traditional manual sandblasting can only process a few dozen small workpieces per day, failing to keep up with production schedules. For outdoor repairs, the equipment cannot be moved, forcing sandblasting to be abandoned and manual polishing to be used instead.

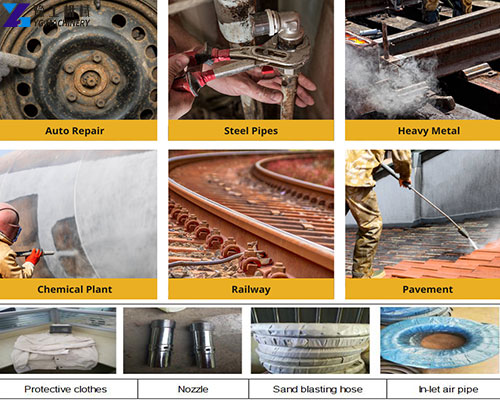

YG’s sand blasting machine with compressor integrates the sandblasting machine and compressor, eliminating the need for separate equipment and enabling immediate operation. The machine is available in industrial, automatic, and portable models for various applications, ensuring the right equipment for every application, from factory-based batch processing to outdoor repairs and small workshop production. To date, our equipment has been exported to Southeast Asia, Europe, and other regions, helping customers such as auto parts manufacturers, hardware fabricators, and repair shops solve surface treatment challenges. For example, a Chilean auto parts manufacturer has seen a 40% increase in rust removal efficiency after using our industrial sand blasting machine, processing over 3,000 additional parts per month. If you’re interested, please contact us now for more product information and the latest price quote.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Sand Blasting Machine Parameter

| Machine models | YG400 | YG500 | YG600 | YG700 | YG800 | YG900 | YG1000 |

| Diameters(mm) | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Height(mm) | 1150 | 1150 | 1150 | 1250 | 1700 | 2000 | 2000 |

| Volume(cubic meter) | 0.26 | 0.26 | 0.26 | 0.3 | 0.6 | 0.8 | 1 |

| Pressure(Mpa) | 0.4-8 | ||||||

| Air consumption(cubic meters per minute) | 3 | ||||||

How to Choose the Right Sand Blasting Machine with Compressor? A 4-Step Selection Guide

1. Identify the use case: First, determine “where and what it will be used for.”

If you’re processing large workpieces in a factory, choose an industrial sand blasting machine. If you’re doing outdoor maintenance or small-batch work, choose a portable sand blasting machine. If you need high-precision, automated production, choose an automatic sand blasting machine.

2. Determine your processing requirements: Consider “efficiency and accuracy.”

For example, if you need to process 1,000 small parts per day, an industrial sand blasting machine with a multi-nozzle design is more suitable. If your workpieces require high-precision sandblasting (such as medical device parts), an automatic sandblasting machine with PLC control will meet your needs. If you only process a few workpieces occasionally, a portable sand blasting machine is more cost-effective.

3. Choose the Right Compressor Power: Avoid “Insufficient Pressure”

Compressor power directly impacts sandblasting results: For thin workpieces (such as sheet metal), choose a 5.5-7.5kW compressor; for heavy workpieces (such as steel plates and pipes), choose a compressor with 11kW or higher. Our equipment will pair with the appropriate compressor based on the machine model, eliminating the need for you to calculate separately. For example, industrial models are defaulted to a 15kW compressor, while portable models are defaulted to a 3kW gasoline compressor.

4. Consider After-Sales Service: After-Sales Guarantee is Essential

When choosing a sandblasting machine with a compressor, be sure to consider the manufacturer’s after-sales service capabilities. For example, we offer free installation and commissioning, free part replacement for quality issues, and customizable accessories (such as additional blasting heads or larger abrasive tanks) are also available.

FAQs: About the YG Sand Blasting Machine with Compressor

Q1: Can your sand blasting machine with a compressor process materials such as stainless steel and aluminum alloy?

A1: Yes. We recommend the appropriate sandblasting abrasive for different workpiece materials (e.g., glass beads for stainless steel, aluminum oxide grit for aluminum alloy) and adjust the compressor pressure accordingly. For example, for aluminum alloy, we adjust the pressure to 0.4-0.6 MPa to prevent excessive pressure from causing workpiece deformation.

Q2: Does the gasoline compressor in your portable sandblasting equipment consume a lot of fuel?

A2: Not at all. Our gasoline compressor is energy-efficient, consuming approximately 1.5-2 liters of fuel per hour. A full tank of 10 liters of fuel can provide 4-6 hours of continuous operation, sufficient for a full day of outdoor work.

Q3: Can the automatic sandblasting machine handle my workpiece’s unusual shape?

A3: It can be customized. Our automatic sandblasting machine supports custom nozzle count and angles. For example, for workpieces with grooves or holes, we can design side and bottom nozzles to ensure perfect sandblasting.

![]()