Are you struggling with the dust pollution, environmental fines, and expensive abrasive consumption associated with traditional open-air sandblasting operations? In the face of increasingly stringent global environmental regulations, inefficient and highly polluting surface treatment methods have become a major obstacle to business operations. The YG shot blasting booth is a solution tailored to end these pain points. Our equipment creates a completely enclosed shot blasting room, coupled with our proprietary negative pressure dust removal system, ensuring that particulate matter emissions remain below safe standards throughout the operation, allowing your business to pass environmental audits easily. More importantly, our innovative all-terrain mechanical recycling system and highly efficient abrasive separation technology ensure that over 98% of the used abrasive is recycled and purified, significantly reducing your abrasive procurement costs. Choosing the YG shot blasting booth gives you not only a compliant working space but also a profitable tool that significantly improves operational efficiency, reduces long-term costs, and enhances your company’s environmental image. Contact us now for product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Shot Blasting Booth Parameter

| Size of Blasting Room | Size of workpieces | Blasting Gun Qty |

| 6000×6000×5000mm | 3000×3000×2500mm | 2 |

| 6000×6000×6000mm | 3000×3000×3500mm | 2 |

| 8000×6000×5000mm | 5000×3000×2500mm | 2 |

| 8000×6000×6000mm | 5000×3000×3500mm | 2 |

| 10000×6000×6000mm | 7000×3000×3500mm | 2 |

| 15000×6000×6000mm | 12000×3000×3500mm | 2 |

| 15000×8000×6000mm | 12000×5000×3500mm | 2 |

| 18000×8000×6000mm | 15000×5000×3500mm | 4 |

| 18000×10000×8000mm | 15000×7000×5500mm | 4 |

How a Shot Blasting Booth Works?

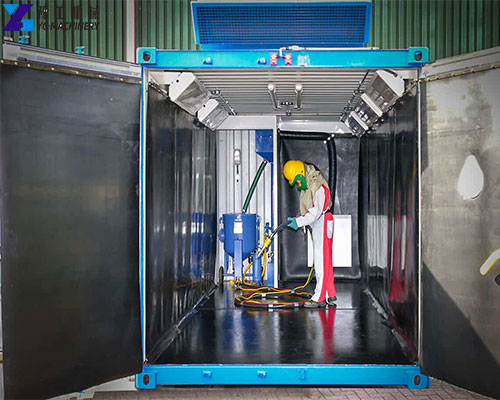

- Work Process: The operator, wearing protective gear, uses a high-pressure blasting gun in a sealed chamber to propel abrasive materials (such as steel shot or grit) carried by compressed air onto the workpiece surface.

- Abrasive Recovery: Abrasive and dust particles settle into an underground recovery pit under gravity.

- Mechanical Conveying: The abrasive in the pit is conveyed to a bucket elevator outside the booth via a scraper conveyor or screw conveyor.

- Separation and Purification: The elevator lifts the abrasive to a separator at the top, where air classification separates reusable qualified abrasive, ultrafine dust, and coarse impurities. A qualified abrasive enters a storage silo for reuse.

- Dust Removal and Purification: Dust inside the booth is extracted and purified by a dust collector to ensure the air environment meets safety standards.

YG Shot Blasting Booth Core Functions and Technical Advantages

- Highly efficient and uniform shot blasting: Even shot coverage quickly removes rust, scale, and other impurities, far exceeding the efficiency of manual grinding, and is suitable for various workpiece sizes.

- Intelligent dust control: Dual dust purification system with negative pressure design inside the chamber prevents dust overflow; purified exhaust emissions meet global environmental standards.

- Abrasive recycling: High recycling efficiency reduces abrasive waste and lowers consumable costs.

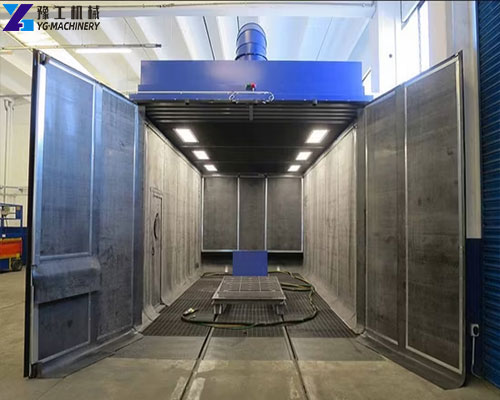

- Modular and rapid installation: Factory-prefabricated components allow for simple and quick on-site installation, and flexible disassembly and relocation, making it more convenient than an integrated shot blasting room.

- Comprehensive safety protection: Equipped with observation windows, emergency stop buttons, and other safety features; the operating area is physically isolated from the work chamber, ensuring operator safety.

- Suitable for various workpieces: Processes various metal workpieces; when paired with a hanger-type shot blasting machine, it can handle longer workpieces, meeting diverse needs.

- Precisely adjustable parameters: Parameters such as shot blasting speed and processing time can be adjusted via a touchscreen, allowing for optimal processing of different workpiece materials.

Brazilian and Indonesian Customers Purchase YG’s Sandblasting Booths

Case Study 1: Brazilian Heavy Machinery Manufacturer

- Client Background: A large Brazilian manufacturer of construction machinery and mining equipment needed to process large castings such as excavator arms and buckets, requiring extremely high surface cleanliness.

- Problem Solved: The client’s existing equipment was an outdated drum-type shot blasting machine, unable to handle large, non-standard workpieces, and generating severe dust pollution.

- Product Used: YG customised 25m shot blasting booth, equipped with a full-surface mechanical recovery system.

- Results: The client solved the pre-treatment problem of large workpieces using the shot blasting booth, and the product coating adhesion passed rigorous salt spray testing. This allowed the client to replace their old hanger-type shot blasting machine, significantly increasing overall production capacity.

- Customer Testimonial: “YG’s shot blasting room is extremely reliable, and the ground-based recycling system is highly efficient with virtually no abrasive waste. Most importantly, it helped us meet the highest surface treatment requirements of our international clients.”

Case Study 2: Indonesian Shipyard

- Client Background: A medium-sized shipyard in Indonesia needs to regularly sandblast and protect hull sections from corrosion, requiring equipment capable of withstanding high humidity and continuous operation.

- Problem Solved: How to efficiently and environmentally process hull sections within a limited space, while closely coordinating with the painting process.

- Product Used: YG 18m shot blasting booth, with a specially customised high-efficiency dehumidification system.

- Results: The YG shot blasting booth ensured continuous and stable operation in humid climates, preventing rust re-emergence on the steel surface. The client found that using the shot blasting booth was more flexible than using a pass-through shot blasting machine, especially suitable for processing large, irregular sections.

- Customer Testimonial: “The durability of YG equipment is perfectly suited to our seaside environment. We know that without YG’s shot blasting booth, our boats wouldn’t have the 20-year corrosion guarantee.”

An Alternative to a Fixed Shot Blasting Room: How Can a Portable Sand Blasting Booth Address Temporary or Large Project Needs with the Advantages of Low Cost and Rapid Deployment?

Traditional shot blasting rooms face high civil engineering costs, long construction cycles, and the limitation of immobile sites, making them unaffordable for many temporary projects or space-constrained businesses. The core advantage of the YG portable sand blasting booth lies in its extremely low cost and rapid deployment capability. Utilising a modular, scalable, flexible structure, it eliminates the need for expensive permanent pits and infrastructure investments, saving up to 70% on initial construction costs. Furthermore, the entire system can be installed and commissioned in just 1 to 3 days, enabling rapid deployment and perfectly adapting to short-term or urgent project needs. Despite its portability, the portable sand blasting booth is not lacking in functionality. It integrates a highly efficient abrasive recovery and dust removal system, ensuring a sealed working environment and environmental compliance, with dust emissions meeting the highest standards. This flexibility allows companies to adjust production capacity or relocate equipment at any time according to project changes, greatly improving asset utilisation and production layout flexibility. In summary, for contractors, rental companies, or businesses needing to handle large, irregularly shaped workpieces, the YG portable sand blasting booth, with its high cost-effectiveness and excellent mobility, is the ideal and most economical alternative to a fixed shot blasting room. Contact YG now for more product information.

Shot Blasting Booth Manufacturer – YG Machinery Factory

Your project won’t be limited by standard equipment. The biggest advantage of YG shot blasting booths lies in their unlimited customisation capabilities. Whether handling extra-long, extra-wide structural components or complex-shaped castings, we can tailor the most suitable shot blasting room solution for you, ensuring the highest cleanliness standards are achieved in every corner. This perfect adaptability to non-standard workpieces will significantly enhance your market competitiveness.

We are committed to providing end-to-end solutions. In addition to the core shot blasting booth, we also offer a variety of professional supporting equipment to enhance your productivity. This includes industrial vacuum cleaners for efficient cleaning, mobile lighting beacons for operator safety, and high-performance air compressors for pneumatic tools and sandblasting machines. For customers who need to adjust their production lines quickly, we even offer portable sand blasting booths for added functionality. Break free from size and process limitations! Contact YG’s professional team today, tell us your maximum workpiece size and unique process requirements, and let us customise a complete equipment procurement plan for you, achieving the convenience and price advantage of one-stop purchasing. Contact us now!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()