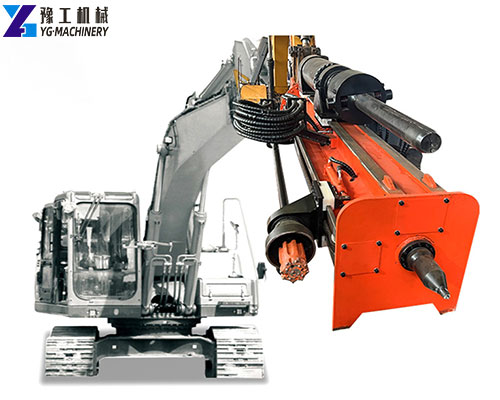

In rock engineering projects, controlling equipment costs and operational efficiency are crucial to project profitability. Traditional rock breaking solutions typically require three types of equipment working together: a drilling rig, a separate high-pressure pump station, and a hydraulic breaker. This not only means high initial investment and complex maintenance, but also requires multiple operators and significant fuel consumption, resulting in high operating costs. The YG integrated hydraulic rock drill and splitter, as an excavator accessory, cleverly utilizes your existing excavator on-site as a power source and platform. This not only eliminates the huge cost of purchasing separate chassis and engines, but also significantly reduces additional fuel consumption and labor costs by directly driving drilling and splitting functions through the excavator’s hydraulic system. This “one machine, multiple uses, integrated functions” feature rapidly increases your return on investment. The purchase and maintenance costs of this integrated hydraulic rock drill and splitter are far lower than the combined costs of three separate pieces of equipment, making it a core competitive advantage for maximizing profits in a highly competitive market. Contact us now for product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Integrated Hydraulic Rock Drill and Splitter Parameter

| Model | YG-1500 |

| Drill depth | 1500 mm |

| Borehole diameter | 125 mm |

| Drill-split per borehole | 5 minutes |

| Power | 22kw |

| Drilling speed | 1 m/min |

| Splitting depth | 1000mm |

| Splitting force | 8000T |

| Rotation angle | 120° |

| Max. propulsion force | 25kn |

| Max. pullout force | 70kn |

| Displacement | 4.5m³/min |

| Exhaust pressure | 5-8Bar |

| Dust filter | 8pcs |

| Lateral thrust | 10kn |

| lateral push speed | 20m/Min |

| Gyrator rotating speed | 1 rpm |

| Gyrator torque | 18kn.m |

| Oil injection volume | 20ml |

| Machine Parameters | |

| Gross weight | 3200kg |

| Total length | 4280mm |

| Overall width | 1182mm |

| Total height | 1490mm |

| Excavator | ≥ 20Ton |

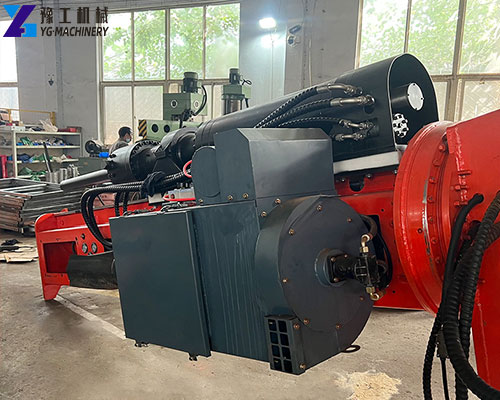

The Core Structure of the YG Integrated Drilling and Splitting Machine Consists Of:

- Coupling Arm and Quick Hitch: For quick and stable connection with various excavator models, utilizing the excavator’s hydraulic power source.

- Drilling Unit: Equipped with a high-frequency hydraulic impactor and rotating device for rapid and precise drilling into hard rock. This is a prerequisite for static splitting.

- Splitting Unit: Composed of high-strength alloy wedges and ultra-high-pressure hydraulic cylinders, it breaks rock by applying an enormous expansion force.

- Integrated Hydraulic Valve Group: Precisely controls the switching between drilling and splitting modes, ensuring stable system pressure and flow.

6 Features & Specifications of YG Integrated Hydraulic Rock Drill and Splitter

- Integrated Drilling and Splitting Design: No equipment replacement is required; one machine can complete the entire “drilling-splitting” process, saving 50% of equipment changeover time and increasing work efficiency by 60% compared to using a separate drilling machine and splitter. This is especially suitable for infrastructure projects with tight deadlines.

- Wide Power Compatibility: Compatible with 20-30 ton excavators. The hydraulic flow can be adjusted to suit different excavator powers. Drilling speed is 80-120mm/minute (granite geology), and splitting time is ≤30 seconds/hole, making it 20% more efficient than similar integrated rock drilling splitting machines for excavators.

- Multi-Rock Adaptability: The drilling module supports Φ40-80mm drill bit replacement, and the splitting module can adjust the splitting force (300-500 tons) according to the rock type. It can handle various hard rocks such as granite, limestone, and basalt, adapting to different needs in mining, infrastructure, and other scenarios.

- Intelligent Safety Protection: Equipped with a hydraulic overload protection system, it automatically releases pressure when the splitting force exceeds the set value to prevent equipment damage; the drilling module has an anti-jamming device that automatically adjusts the rotation speed when encountering rock fissures to reduce drill bit wear.

- Convenient Operation and Control: Linked to the excavator cab control, operators can control drilling, splitting, and angle adjustment using only two levers. No additional training is required; new operators can become proficient within one hour.

- Quick Maintenance Design: The drilling and splitting modules adopt an independent, detachable structure, allowing drill bit/split wedge replacement in just 10 minutes; the hydraulic interfaces feature a dustproof, sealed design, reducing hydraulic system failures, with an average of ≤2 maintenance visits per year.

Feedback from German and Canadian Customers Using the YG Drilling and Splitting Machine

Case Study 1: Berlin Metro Expansion Project, Germany

- Client Background: A well-known German underground engineering company was responsible for the rock excavation of a new metro line in central Berlin. The project had stringent restrictions on noise and vibration, prohibiting the use of conventional blasting.

- Problem Solved: A solution was needed for efficient, non-blasting rock breaking in narrow underground tunnels.

- Product Used: YG medium-sized integrated hydraulic rock drill and splitter (compatible with a 25T excavator).

- Results: The client used this hydraulic rock drilling and splitting machine for continuous operation, drilling first and then breaking. The splitting process resulted in minimal vibration, fully complying with urban environmental monitoring standards. Due to the integrated drilling function, daily excavation efficiency increased by 40% compared to using a splitter alone.

- Customer Testimonial: “Working in downtown Berlin, safety and low vibration are our lifelines. YG’s integrated hydraulic rock drill and splitter helped us solve all our problems. Its integrated design made the workflow exceptionally smooth, truly achieving efficient rock breaking without blasting.”

Case Study 2: Upgrade and Renovation of a Large Quarry in Quebec, Canada

- Customer Background: A large stone quarry in Quebec, Canada, sought a new technology to replace traditional secondary blasting to improve the integrity of the output and the utilization rate of the stone.

- Problem Solved: Traditional blasting easily causes excessive stone fragmentation and affects the safety of the surrounding environment. A tool was needed for precise, static splitting of giant rocks.

- Product Used: YG Heavy-Duty Integrated Hydraulic Rock Drill and Splitter (compatible with a 35T excavator).

- Results: The customer used the equipment as an integrated rock drilling and splitting machine for excavators to perform secondary crushing of large quarried rock blocks. Static splitting avoids impact and vibration, ensuring that the final output stones are more uniform in size and have higher integrity, increasing the utilization rate of the stone by nearly 15%.

- Customer Testimonial: “We are delighted with its efficiency and splitting force. Previously, we needed two machines, but now one YG integrated hydraulic rock drill and splitter can handle it, saving a lot of time and labor costs.”

Integrated Hydraulic Rock Drill and Splitter for Sale – YG Machinery

The advent of the YG integrated hydraulic rock drill and splitter marks a new era of static, precise, and efficient rock engineering. The technological pride of this equipment lies in its perfect solution to a long-standing core challenge in the industry: how to maintain rock-breaking efficiency comparable to traditional blasting without generating harmful vibrations and noise.

The core technological advantage of this equipment lies in the seamless integration of its high-frequency hydraulic drilling unit and ultra-high-pressure splitting system. The hydraulic system provides a powerful, instantaneous splitting force sufficient to overcome the tensile strength of even the hardest rocks. Simultaneously, as an attachment to the integrated rock drilling splitting machine for excavators, it fully utilizes the multi-angle working capabilities of excavators, enabling precise rock splitting in confined and complex spaces inaccessible to traditional equipment, such as tunnel excavation, foundation pit edges, or cliff faces. This superior operational flexibility and technical stability have earned the YG integrated hydraulic rock drill and splitter widespread recognition in global tunneling, quarrying, and mining engineering.

For special rock engineering challenges that prohibit blasting and demand high efficiency, you need a state-of-the-art solution! We can share videos of rocks of varying hardness with you immediately. Of course, we will also provide you with the most suitable solution from a professional perspective.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()