Metales Dinámicos is a well-known heavy metal structure manufacturer in Mexico, serving multiple fields such as construction, energy, and infrastructure. With the growth of business and the improvement of customer requirements for surface treatment quality, their original manual grinding and local sandblasting methods can no longer meet the needs and become a production bottleneck. To solve this problem, Metales Dinámicos chose to cooperate with us. They introduced an advanced customized shot blasting room system, which successfully realized the modernization of the surface treatment process and significantly improved production efficiency, product quality, and working environment safety. Please contact us now if you also need a customized sandblasting room solution.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Shot Blasting Room Parameter

| Size of Blasting Room | Size of workpieces | Blasting Gun Qty |

| 6000×6000×5000mm | 3000×3000×2500mm | 2 |

| 6000×6000×6000mm | 3000×3000×3500mm | 2 |

| 8000×6000×5000mm | 5000×3000×2500mm | 2 |

| 8000×6000×6000mm | 5000×3000×3500mm | 2 |

| 10000×6000×6000mm | 7000×3000×3500mm | 2 |

| 15000×6000×6000mm | 12000×3000×3500mm | 2 |

| 15000×8000×6000mm | 12000×5000×3500mm | 2 |

| 18000×8000×6000mm | 15000×5000×3500mm | 4 |

| 18000×10000×8000mm | 15000×7000×5500mm | 4 |

Before the Introduction of the Shot Blasting Room, The Traditional Processing Methods of Mexican Customers

- Manual grinding and angle grinding: low efficiency, high labor intensity, uneven surface treatment effect, difficult to achieve consistent roughness requirements, especially for large and complex structural parts, and very time-consuming.

- Local mobile sandblasting equipment: limited flexibility, only suitable for small or local areas. Severe dust pollution during operation requires a lot of protective measures and poses potential risks to the health of operators. Cleaning work is cumbersome.

- Production bottleneck: The processing speed of the surface treatment link is much slower than other processing links, resulting in an extension of the overall production cycle and affecting delivery capabilities.

- Quality consistency issues: It is difficult to ensure the stable and reliable surface treatment quality of each batch and each workpiece, which affects the adhesion and durability of subsequent spraying or galvanizing.

- Environmental and safety pressure: The dust and noise generated by traditional methods have an impact on the working environment and surrounding communities, and face the increasingly stringent environmental regulations in Mexico.

Metales Dinámicos urgently needs an overall solution that can process large components of various sizes, provide uniform and high-quality surfaces, and be efficient, environmentally friendly, and safe.

YG’s Customized Sandblasting Room Solution:

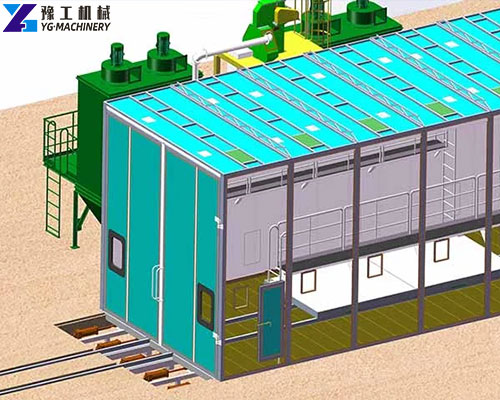

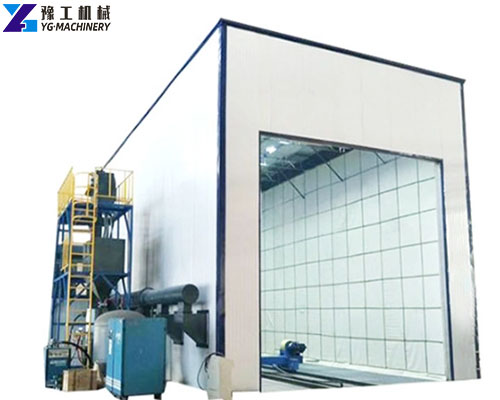

After an in-depth understanding of Metales Dinámicos’ specific needs (including the maximum size of the components to be processed, annual production, desired surface roughness, and site conditions), our professional team designed and customized a large walk-in shot blasting room for them.

Features of the sandblasting room:

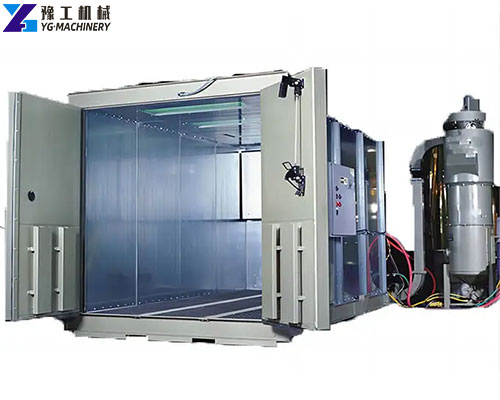

- Customized shot blasting room: Precisely designed according to the maximum component size processed by the customer, ensuring that all workpieces can be easily entered and exited and fully processed inside. The sturdy room structure and professional sealing design effectively control the escape of projectiles and dust.

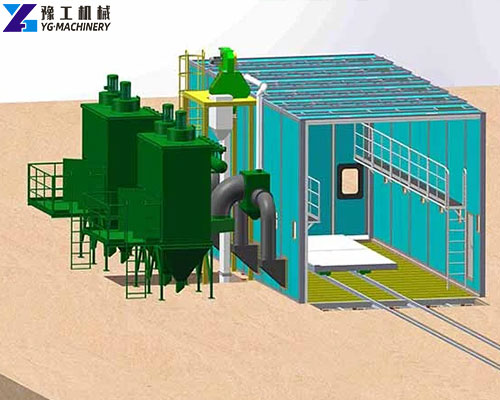

- Efficient projectile recovery and separation system: Integrates advanced screw conveyors, bucket elevators and efficient shot slag separators to achieve automatic recovery, cleaning and recycling of projectiles, greatly reducing the cost of projectile consumption.

- Powerful dust removal system: Equipped with high-performance bag dust collectors or cartridge dust collectors, it effectively captures dust generated during the shot blasting process, ensures that the air quality inside and outside the portable sandblasting booth meets environmental protection standards, and improves the working environment of workers.

- Safety and automation control: Multiple safety interlocks (such as gate interlocks, access door interlocks, etc.) and intuitive electrical control systems are integrated to ensure safe and reliable operation. Adequate internal lighting facilitates workers’ operations and inspections.

- Wear-resistant protective lining: The key areas inside the shot blasting room are protected by highly wear-resistant materials to extend the service life of the equipment and reduce maintenance.

- Localized support: Considering that the customer is in Mexico, we provide a one-stop service including equipment transportation, on-site installation guidance, commissioning, and operation and maintenance training. Our technical team works closely with Metales Dinámicos’ engineers to ensure the smooth commissioning of the equipment and provide subsequent spare parts supply and technical support.

Significant Results and Benefits Achieved by Customers:

- Production efficiency has been greatly improved: The speed of shot blasting is much faster than traditional methods, shortening the surface treatment of complex components that originally took hours or even days to complete to tens of minutes or hours, and the overall production efficiency has been improved by more than 50%.

- Significant improvement in surface treatment quality: Obtaining uniform and consistent surface cleanliness and roughness of Sa2.5 or higher standards provides an ideal foundation for subsequent spraying or galvanizing, greatly enhancing coating adhesion and product durability. Customers reported that the coating quality is more stable and reliable.

- Reduced operating costs: The shot recovery system effectively reduces the purchase of new shot; improved processing efficiency reduces energy consumption and labor costs per unit workpiece; longer equipment life and lower maintenance requirements also reduce long-term operating costs.

- Working environment optimization and safety improvement: The efficient dust removal system completely solves the dust pollution problem, and the working environment becomes cleaner; the closed operation and safety interlocking devices greatly improve operational safety and reduce the risk of work-related injuries; it complies with the stricter local occupational health and safety regulations in Mexico.

- Enhanced market competitiveness: Higher production efficiency, stable product quality, and faster delivery cycle help Metales Dinámicos stand out in the fiercely competitive market and win the trust of more high-end projects and customers.

Sand Blasting Chamber Customer Comments:

Metales Dinámicos’ Production Manager said: “The previous surface treatment method has been a problem that has troubled us for many years. It is inefficient, dusty, and has unstable quality. Cooperating with YG Machinery to introduce this shot blasting room is one of the best decisions we have made. Their professional team not only provides excellent customized equipment but also provides strong support in installation and training. Now, our surface treatment speed is more than twice as fast, the quality has reached an unprecedented level, and the working environment of the workers has also been greatly improved. This is a very valuable investment, and the return will be seen soon.”

Sandblasting Cabinet for Sale – YG Machinery:

By providing a customized large-scale shot blasting room solution for Metales Dinámicos, a Mexican metal processing plant, we not only helped customers overcome production bottlenecks and quality problems but also improved their overall operational efficiency, environmental protection level, and market competitiveness. This case fully demonstrates our strength in surface treatment technology and global project delivery, especially our professional ability to understand and meet the unique needs of emerging industrial markets such as Mexico. If you are also a company in the metal processing, steel structure manufacturing, automotive parts, casting, and other industries in Mexico or Latin America, facing similar surface treatment challenges and looking for efficient, environmentally friendly, and reliable solutions, please contact us. Our team of experts will tailor the best shot blasting equipment solution for you according to your specific needs.

![]()