Are you facing the problems of low slitting efficiency, high labor costs, or unstable product quality? Choose the YG automatic slitting machine and change the status quo immediately! Our automatic slitting machine can significantly improve your production speed and automation level, and greatly reduce labor expenses. More importantly, it guarantees extremely high slitting accuracy and winding quality, effectively reduces material waste, and directly reduces production costs. Investing in a YG automatic slitting machine means investing in higher production capacity, more stable quality, and faster return on investment. Let automation help you stand out in the fierce market competition! Contact us now for product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Automatic Slitting Machine Parameter

| Model | YG- 1300 | YG- 1600 | YG- 1800 |

| Max width | 1300mm | 1600mm | 1800mm |

| Max Diameter for unwinding | ¢1400mm | ¢1400mm | ¢1400mm |

| Minimum width of slitting | 30mm | 30mm | 30mm |

| Max Diameter of rewinding | ¢1000mm | ¢1000mm | ¢1000mm |

| Speed | ≤350m/min | ≤350m/min | ≤350m/min |

| Total Power | 24kw | 26kw | 30kw |

| Power supply | 380V/50hz | 380V/50hz | 380V/50hz |

| Weight | 4000kg | 4500kg | 5500kg |

| Overall dimension(LxWxH) | 3300x3150x1930(mm) | 3300x3450x1930(mm) | 3300x3650x1930(mm) |

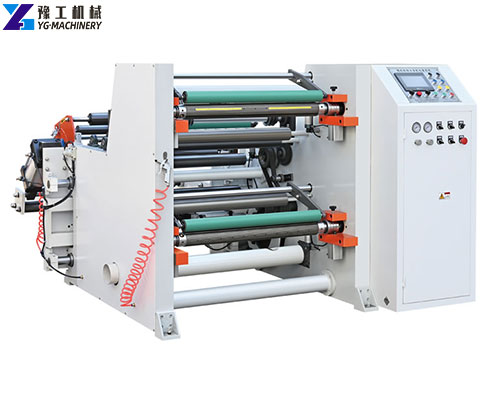

Paper Slitter Rewinder Machine Product Description

- YG’s automatic slitter machine combines advanced technology with a rugged design and is designed for efficient and high-precision processing of various roll materials. The overall structure of the equipment is compact, with a small footprint, but powerful. It is mainly composed of an unwinding section, a slitting section, a rewinding section, and an intelligent control system.

- The unwinding section adopts an advanced shaftless or shafted pneumatic structure, which can stably clamp and accurately control the tension of the parent roll material to ensure that the material enters the slitting area smoothly.

- The slitting section is the core of the equipment, equipped with high-precision knives (circular knives, straight knives, or pressure cutters can be selected according to the material). These knives are precisely arranged and adjusted to quickly and accurately cut large rolls longitudinally into multiple narrow rolls of preset width. The installation and adjustment of the knives are convenient and quick to adapt to different slitting requirements.

- The rewinding section uses an independent tension control system to ensure that each narrow roll, after slitting, can be wound onto the new roll core with uniform tension and neat end faces to avoid loose rolls or tower rolls. The reel adopts a differential speed or center/surface winding method to adapt to different materials and winding requirements.

- The frame structure of the equipment is made of high-quality high-strength steel, and is precision welded and aging treated to ensure the stability and durability of the equipment under high-speed operation. Key transmission components are all selected from internationally renowned brands to ensure long-term, reliable operation.

A German Printing Plant Optimizes the Quality of Paper Rolls by Using YG’s Slitter Rewinder

A well-known German printing plant focuses on the production of high-quality commercial printed materials. It needs to process a large number of rolls of paper of different specifications. It has very high requirements for the stability and ease of use of the paper slitter rewinder machine and the quality of the slit paper rolls. After many investigations, they finally chose an automatic slitting device dedicated to paper processing from YG. After the equipment was put into use, the operators of the printing plant said that the touch screen interface of the equipment was friendly, the operation logic was clear, and the roll change was very convenient and fast, which greatly reduced the difficulty of operation and training time. The technical department reported that the tension of the paper rolls after slitting was uniform, there was no loose edge or tight edge phenomenon, and the winding was very tight and neat, which greatly improved the smoothness of the subsequent printing process and reduced the downtime and waste caused by paper roll quality problems. The customer’s technical director commented: “YG’s paper slitter rewinder is the best solution we have found in the field of paper processing. It is easy to operate, has excellent performance, and the quality of the slit paper rolls is first-class. It helps us improve printing quality and production efficiency. It is a trustworthy partner.”

Automatic Slitting Machine Price and Purchase Information

The price of the YG automatic slitting machine is affected by many factors, including the model of the equipment, the maximum processing width, the maximum speed, the degree of automation, whether it contains special functions (such as automatic loading and unloading, printing correction, remote monitoring, etc.), and the material characteristics requirements. Generally speaking, our equipment offers a market-competitive price range, covering basic models to high-end customized models.

As a manufacturer with independent R&D, production, and sales capabilities, YG can provide you with a more direct and more favorable ex-factory price, and save the middleman price difference. More importantly, factory direct sales means that you can get more professional technical advice, more complete customized services, and more timely and reliable after-sales support.

If you are interested in the YG automatic slitting machine, want to know the detailed configuration and performance parameters of a specific model, or customize a solution according to your particular needs and get an accurate quotation, please feel free to contact us. Our professional team will serve you wholeheartedly and provide detailed product introductions, technical advice, and precise quotations.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()