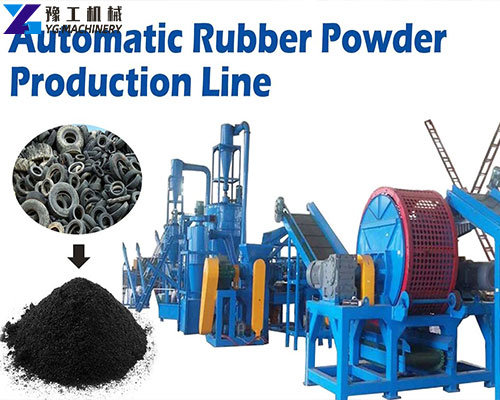

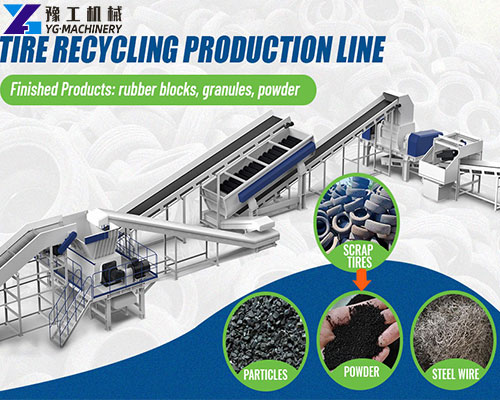

Have you also seen the piles of waste tires on the roadside? Not only do they take up space, but they may also cause fires, breed mosquitoes, and cause considerable trouble to the environment. But do you know? These seemingly useless waste tires contain huge treasures! YG specializes in a complete production line for waste tires, which can turn these discarded tires into useful rubber particles or rubber powder. This waste tire recycling line is simple to operate and highly efficient, like a magic machine that “turns waste into treasure”. First, cut the large tires into pieces, then separate the steel wires and fibers inside, and finally get clean rubber particles. These small particles can be used to pave runways, make floor tiles, and even be mixed into asphalt for road repairs, giving old tires a new life. This production line of YG can not only help you solve environmental problems, but also bring you tangible economic benefits. Contact us now to get more product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Waste Tire Recycling Line Parameter

| Model | YG-3 | YG-6 | YG-10 | YG-16 | YGL-16 | YG-30 |

| Capacity | 1-3t/d | 4-6t/d | 8-10t/d | 12-16t/d | 8t/d (only for rubber powder) | 30-35t/d |

| Working Process | Batch | Batch | Batch | Batch | Semi-continuous | Fully continuous |

| Reactor Size | φ1400*4900mm | φ2200*6000mm | φ2600*6600mm | φ2800*7100mm | φ2800*7100mm | φ1800*18500mm |

| Land (L*W*H) | 18m*4.2m*6m | 30m*12m*8m | 30m*13m*8m | 33m*13m*8m | 33m*13m*8m | 70m*20m*10m |

| Power | 16.65kw | 37.85kw | 44.3kw | 55.6kw | 55.6kw | 256kw |

| Burner | 2*200,000 kcal | 2*300,000 kcal | 2*300,000 kcal | 2*400,000 kcal | 2*400,000 kcal | 2.5 million kcal per set |

| Total Weight of Shipped Materials | About 18t | About 24.5t | About 28t | About 34.5t | About 34.5t | About 150t |

| Noise (dB) | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 |

Working Principle of Waste Tire Recycling Line

The working principle of the YG waste tire recycling line can be summarized as “physical crushing + multi-stage separation”. First, waste tires are sent to the dismantling machine manually or mechanically for steel rim separation. Then, the tires without steel rims are transported to the core tire shredder machine (usually a double-shaft shredder), which uses its powerful shearing and tearing action to crush the whole tire into 50-150mm rubber blocks.

Subsequently, these rubber blocks enter the subsequent crushing equipment (such as a rubber crusher) through the conveyor belt and are further processed into smaller rubber particles. During the crushing process, the strong magnetic separator will effectively adsorb and separate the steel wire. After that, the crushed materials enter the vibrating screening machine for screening, and the unqualified materials will be returned for crushing again. At the same time, the fiber separator uses wind power or electrostatic technology to separate the fine fibers in the rubber. Finally, rubber particles or rubber powder of different specifications and high purity are obtained and collected through the packaging system. The whole process is a continuous automated production line, ensuring efficiency and product quality.

YG’s Tire Recycling Line and Shredder Customer Use Cases and Feedback

Case 1: A large tire recycling center in California, USA

“We have been looking for an efficient and environmentally friendly waste tire recycling line to cope with the growing amount of waste tires. After investigating several suppliers, we chose YG’s solution. Their dual-axle tire shredder machine has excellent performance and can easily handle even heavy truck tires. The entire production line is highly automated, which greatly reduces our operating costs and labor requirements. Now, we can produce more than 500 tons of high-quality rubber particles per month, and sales are very good. YG’s technical support team also provides very professional services, and we are very satisfied with it.”

Case 2: A rubber product manufacturer in Bavaria, Germany

“As a rubber product company, we have very high requirements for the quality of recycled rubber. The tire recycling line provided by YG The rubber powder produced has high purity and uniform particle size, which fully meets our requirements for producing high-quality rubber floor tiles. This not only reduces our raw material procurement costs, but also makes our products more competitive in the market. In particular, YG’s design in equipment details and energy saving has shown us his professionalism as a senior mechanical engineer. We even recommended YG’s products to other peers. ”

Waste Tire Recycling Line Price & Purchase Information

The price of a YG waste tire recycling line varies depending on the configuration, processing volume, degree of automation, and final product particle size requirements. The main factors affecting the tire shredder machine price include its blade material, motor power, shredding capacity, and whether it is equipped with an intelligent control system. As a professional factory-direct sales company, YG can provide you with very competitive prices and comprehensive after-sales service guarantees. We provide a one-stop solution, including equipment selection, solution design, installation and commissioning, personnel training, and lifelong technical support. Contact us now so that we can provide a detailed quotation and customized solutions based on your specific needs and budget.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()