In our daily lives, toilet paper is a necessity that every household cannot do without, so the market for toilet paper production has always been large. For those who want to enter or expand the paper business, it is very important to find a good and cost-effective toilet paper production machine. YG has many years of experience in machinery manufacturing and specializes in providing advanced toilet paper production equipment to customers around the world. This article will introduce in detail the advantages of toilet paper machines produced by YG, and focus on telling you the key factors that affect the price of toilet paper production machines, hoping to help you make a smart investment decision. Do you want to join this investment business quickly? Contact us now.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Toilet Roll Making Machine Parameter

| YG-1880R Automatic Rewinder | |

| Finished roll diameter | 40-200mm |

| Paper Weight | 13-18gsm single layer |

| Jumbo Roll Width | Max 2200mm |

| Jumbo Roll Diameter | Max φ1200mm |

| Paper Core Inner Diameter | 76.2mm |

| Speed | 150-280m/min |

| Host Power | 380V/50HZ/3PH, 5.5kw |

| Weight | 2800kg |

| Dimensions | 6500x3650x1750mm |

| YG-1880C Automatic Cutter | |

| Cutting speed | 150-180 cuts/min |

| Raw roll length | Max 2200mm |

| Cutting channel | 1 |

| Cut length | Max 400mm |

| Cut Diameter | 60~130mm |

| Total power | 380V/50HZ/3PH, 6KW |

| Paper cutting accuracy | ±1MM |

| Weight | 1800kg |

| Dimensions | 3850x1100x1850mm |

| YG-240 Automatic Packaging machine | |

| Input roll width | 60-160mm |

| Input roll diameter | 80-120mm |

| Packed bag width | Max 240mm |

| Packed bag length | Max 600mm |

| Packing Speed | 10 bags/min |

| Total power | 2.2KW |

| Weight | 800kg |

| Dimensions | 5000x1000x14500mm |

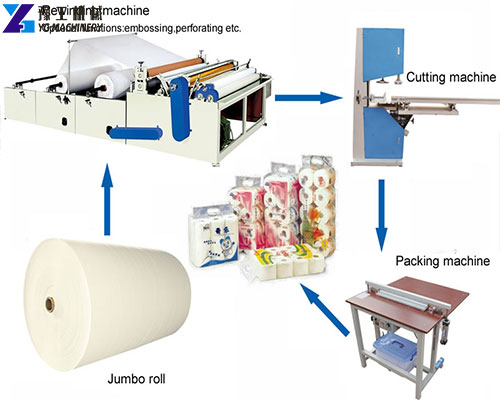

Working Principle of YG Tissue Production Machine

Mainly the unwinding, processing, winding, and cutting of base paper rolls.

- First, a huge base paper roll (usually a large roll formed by processing waste paper pulp) is placed on the unwinding unit. Through the tension control system, the base paper is smoothly and evenly unrolled and fed into the machine.

- Next, the unrolled paper will pass through the embossing unit (if necessary), where the embossing roller will press the surface of the paper to form various exquisite patterns, while also increasing the thickness and softness of the paper.

- Next is the punching and slitting unit, where the sharp knife will punch easy-to-tear dot lines (punch holes) on the paper according to the preset spacing, and at the same time slit the paper into the required width.

- Then, the processed paper strip enters the core winding unit. Here, the servo motor accurately controls the rotation speed and direction of the core rod (the central axis of the paper roll), and the paper strip is tightly and evenly wound layer by layer and circle by circle to form a standard large roll of toilet paper. When the set length is reached, the machine will automatically spray the tail glue and seal it to fix the end of the paper roll.

- Finally, these large rolls of toilet paper will be fed into the sawing unit (if configured), and the sharp saw blade will accurately cut the large rolls into small toilet paper rolls according to the preset size, which are the finished products we use in our daily lives. The whole process is highly automated and closely linked, ensuring efficient and accurate production.

Functional Features of YG’s Toilet Paper Production Machine

- Highly automated control: It adopts an advanced PLC programming control system and touchscreen operation interface to achieve one-button start and fault self-diagnosis, greatly reducing the intensity and error of manual operation.

- High production efficiency: Equipped with a high-speed operation mechanism, the production speed can reach 150-250 meters/minute, effectively improving production capacity and shortening the delivery cycle.

- Stable product quality: Accurate tension control, embossing depth adjustment, and winding density control ensure that the finished toilet paper roll has consistent size, moderate tightness, and high aesthetics.

- Energy saving: Optimize the motor and transmission system, adopt variable frequency speed regulation technology, effectively reduce operating energy consumption, and reduce production costs.

- Strong safety and reliability: It is equipped with multiple safety devices such as an emergency stop button, safety shield, overload protection, etc., to ensure the safety of operators.

- Wide adaptability: It can handle base paper of various specifications and weights, and can adjust product size, embossing pattern, and punching spacing according to market demand to meet diversified production needs.

Customer Feedback and Evaluation of Toilet Roll Production Line

Case 1: Emerging Paper Company in Nigeria

“Our company has just entered the field of toilet roll production and is very cautious in choosing equipment. After comparing multiple suppliers, we finally chose YG’s fully automatic toilet roll production machine. We are very satisfied with the performance of this machine! It is very easy to operate and highly automated, which greatly reduces our need for skilled workers. More importantly, its production efficiency exceeded our expectations and helped us quickly occupy the local market. We thought the toilet roll-making machine price would be very high, but the price offered by YG was very reasonable, and the after-sales service response was also very fast, which solved our worries. Now we are considering purchasing a second production line from YG to expand production capacity.”

——Adebayo K., Nigeria (General Manager of an emerging paper company)

Case 2: Medium-sized paper mill in Hanoi, Vietnam

“As a paper mill with many years of experience, we have been looking for new equipment that can improve production efficiency and reduce costs. YG’s toilet paper production machine perfectly meets our needs. In particular, its embossing and perforating unit design is very sophisticated. The toilet paper produced is not only soft but also very beautiful in appearance, which is deeply loved by our customers. The equipment runs very stably with a low failure rate, which saves us a lot of maintenance time and cost. Although we also compared different models of toilet paper production machines, YG has the highest overall cost performance. Their technical support team is also very professional, helping us complete the installation and commissioning of the equipment and providing detailed training.”

Toilet Roll Making Machine Price – YG Machinery

Toilet roll making machine price is one of the most concerned issues for customers. The price of YG’s toilet paper production machine will vary greatly depending on the degree of automation, production capacity (width, speed), configuration (whether it includes embossing, automatic core change, automatic sawing, etc.), and auxiliary equipment (such as packaging machines, conveyor belts, etc.). As a professional machinery manufacturer, YG adheres to the factory direct sales model, without middlemen adding price, to ensure that you get the most competitive toilet roll making machine price. We not only provide high-quality equipment, but also provide comprehensive pre-sales consultation, installation and commissioning, personnel training, and perfect after-sales service. Want to learn more about the YG toilet paper production machine, or get a dedicated quotation plan? Please contact us now.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()