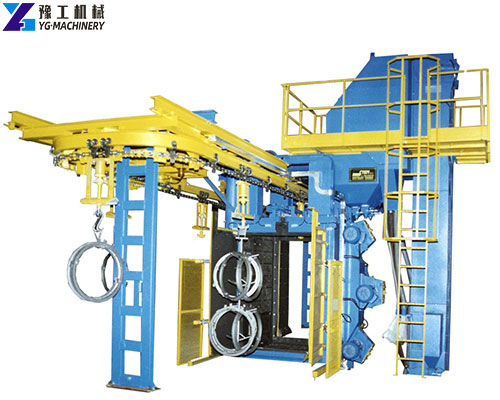

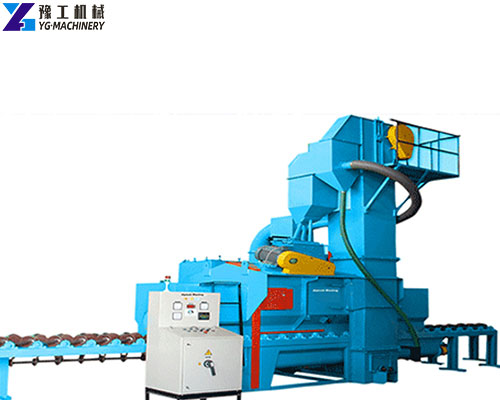

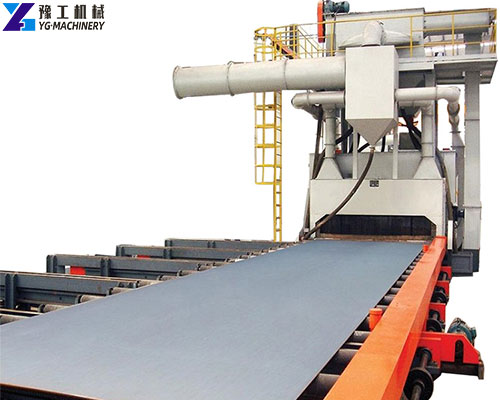

In modern industrial production, the efficiency and quality requirements for metal surface treatment are becoming increasingly stringent. YG’s conveyor type shot blasting machine is born to meet these challenges. It integrates advanced shot blasting technology and intelligent control systems, aiming to provide excellent descaling, rust removal, surface strengthening, and beautification treatment for various metal workpieces. It is widely used in many industries such as automotive parts, castings, forgings, steel structures, profiles, plates, etc. Whether it is mass production assembly line operation or precision processing of a single large workpiece, it can show unparalleled efficiency and excellent surface treatment effect. We provide customized services and can design equipment of different sizes and configurations according to your specific workpiece size, processing volume, and automation requirements, such as a roller conveyor shot blasting machine with various conveying methods, such as flat mesh, catenary, hanging, etc., to maximize your production process. Choosing our through-feed shot blasting machine means choosing higher production efficiency, lower operating cost, and better surface treatment quality. Contact us now for more information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Conveyor Type Shot Blasting Machine Parameter

| Parameter | YG-698 | YG-6912 | YG-6915 | YG-6920 | YG-6925 | YG-6930 | YG-6940 |

| The effective cleaning

width(mm) |

800 | 1200 | 1500 | 2000 | 2500 | 3000 | 4000 |

| The room feed-in

size(mm) |

1000*400 | 1400*400 | 1700*400 | 2200*400 | 2700*800 | 3200*800 | 4200*400 |

| The length of cleaning

The workpiece (mm) |

1200-12000 | 1200-1600 | 1200-12000 | 1200-12000 | 3000-12000 | 2400-12000 | 4500-18000 |

| The speed of the conveyor

(m/min) |

0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| The thickness of the cleaning

steel sheet(mm) |

3-60 | 3-60 | 1.5-60 | 3-60 | 3-60 | 3-110 | 4.5-100 |

| The section steel

specification(mm) |

800*300 | 1000*300 | 1500*300 | 2000*300 | 2500*700 | 3000*700 | 4000*300 |

| The quantity of shots

blasting(kg/min) |

4*180 | 4*250 | 4*250 | 6*250 | 6*250 | 6*360 | 8*360 |

| The first enclosed

quantity(kg) |

4000 | 4000 | 4000 | 4500 | 4500 | 8000 | 11000 |

| Roll brush adjusting

height(mm) |

200 | 200 | 350 | 450 | 600 | 850 | 900 |

| Total power (kW) | 90 | 78.3 | 113.5 | 156.6 | 204.8 | 224.55 | 293.6 |

| Airness size(m3/h) | 22000 | 17560 | 19000 | 19550 | 27758 | 28050 | 38000 |

Features & Specifications of Through-type Shot Blasting Machine

- High-efficiency and continuous cleaning: The workpiece enters the shot blasting room continuously through the conveying system for cleaning, without stopping for loading and unloading, with extremely high production efficiency, especially suitable for processing large quantities of workpieces.

- Excellent cleaning effect: Multiple conveyor type shot blasting machine with large shot blasting volume and high shot blasting speed can blast the workpiece from different angles in all directions, which can effectively remove the oxide scale, rust layer, old paint layer, molding sand, etc. on the surface of the workpiece, and can eliminate surface stress and improve the fatigue strength of the workpiece.

- High degree of automation: From workpiece conveying, shot blasting cleaning, shot recovery and separation to dust collection, the whole process can be automatically controlled, reducing the intensity of manual operation and reducing the impact of human factors on the cleaning effect.

- Wide applicability: According to the size, shape, weight and processing requirements of the workpiece, different specifications of conveyor shot blasting machine can be customized, such as rollers of various widths, conveyor belts of different load-bearing capacities, etc., suitable for a variety of workpieces such as steel plates, steel sections, steel pipes, castings, forgings, welded structural parts, etc.

- Excellent shot circulation system: The precise shot separation device can effectively separate qualified shots, broken shots, and dust, ensure the purity of recycled shots, improve cleaning efficiency, and reduce shot consumption.

- Environmental protection and energy saving: Equipped with an efficient dust removal system, the dust emission concentration is far lower than the national standard, improving the working environment. Optimized shot blasting machine design and energy utilization to achieve energy-saving effects.

- Strong and durable, easy to maintain: The key parts are made of high wear-resistant materials, the equipment structure is reasonably designed, the wearing parts are easy to replace, and the daily maintenance workload is small, ensuring the long-term stable operation of the equipment.

Working Principle of the YG Through-type Shot Blasting Machine

- Workpiece conveying: The workpiece is placed on the conveying system (such as rollers, mesh belts), driven by a variable frequency speed regulating motor, and smoothly enters the shot blasting cleaning chamber at a set speed.

- Shot blasting: When the workpiece enters the effective ejection area of the cleaning chamber, the high-speed rotating shot blasting impeller accelerates the steel shot or steel sand (projectile) and ejects it with extremely high kinetic energy, forming a dense beam of projectiles, which strikes the surface of the workpiece in all directions and at multiple angles. The impact force of the projectile can quickly peel off the oxide scale, rust layer, sticky sand, and other attachments on the surface of the workpiece.

- Projectile circulation and separation: The projectiles after hitting the workpiece and the impurities cleaned up fall into the screw conveyor at the bottom of the cleaning chamber, and then are lifted by the elevator to the separator at the top of the equipment. In the separator, qualified projectiles are separated from broken projectiles, dust, and large debris by air separation and screening. Qualified projectiles enter the storage hopper and are ready to be used by the shot blaster again.

- Dust collection: Dust and fine impurities generated during the cleaning process are sucked away by the dust removal system. The dust-laden airflow is filtered through a dust collector (such as a cartridge or bag type), clean air is discharged into the atmosphere, and dust is collected in a dust box for regular treatment.

- Workpiece output: The cleaned workpiece is moved out of the shot blasting cleaning room along the conveying system and enters the next process.

The entire process is automatically and continuously carried out under the control of the PLC, and each system works together to ensure efficient and uniform surface treatment effects.

Shot Blasting Machine Price & Purchase Information

The price of YG through-type shot blasting machine varies greatly due to its specifications, configuration level, degree of automation, number and power of shot blasting machines, and whether it contains special customized functions (such as fixtures for specific workpieces, robot loading and unloading, etc.).

The main factors affecting the price include:

- The size of the cleaning chamber and the passing capacity of the workpiece determine the basic volume and processing range of the equipment.

- The number and power of the shot blasting machines directly affect the cleaning efficiency and effectiveness.

- The type and carrying capacity of the conveying system, such as roller spacing, load-bearing, mesh belt material, etc.

- Automation and intelligent configuration: such as automatic shot flow control, remote monitoring and diagnosis system, etc.

- The specifications and efficiency of the dust removal system affect environmental protection performance and operating costs.

- The brand and quality of the selected components: brand differences of core components (such as motors, bearings, PLC).

As a professional shot blasting equipment manufacturer, YG insists on factory-direct sales to provide you with the most cost-effective products. Buying directly not only gets you a more favorable price but also offers our comprehensive technical support and after-sales service, including equipment selection consultation, site planning advice, installation and commissioning, operation and maintenance training, and fast spare parts supply. Contact us now for more product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()