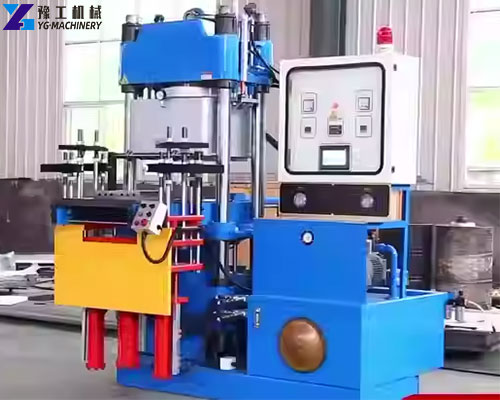

As a key sealing component, the performance of O-rings is directly related to the reliability and safety of equipment, from automobile engines to aerospace equipment, from medical devices to household appliances. Professional vulcanizing equipment is indispensable for manufacturing high-quality, accurate, and durable O-rings. YG’s o-ring vulcanizing equipment mainly consists of a sturdy frame, a heating plate (hot platen), a mold area, and a precise control system. The equipment is usually hydraulically driven. As an advanced hydraulic vulcanizing machine, it can provide stable and uniform pressure to ensure the tight closure of the mold and the full flow of rubber materials during vulcanization. The heating plate has built-in high-efficiency heating elements that can heat up quickly and maintain a constant temperature. The mold is customized according to the size and shape of O-rings and is installed between the heating plates. The entire equipment has a compact structure and an ergonomic design for easy operation and maintenance. If you are interested, don’t hesitate to contact us for more information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

O Ring Vulcanizing Equipment Parameter:

| Model | YG-D/Q

350X350X1(2) |

YG-D/Q

400X400X2 |

YG-D/Q

500X500X2 |

YG-D/Q

600X600X2 |

YG-D/Q

750X850X2(4) |

|

| Nominal pressure(MN) | 0.25 | 0.50 | 0.60/0.80 | 1.00 | 1.60 | |

| Plate size(mm) | 350*350 | 400*400 | 500*500 | 600*600 | 750*850 | |

| Plate clearance(mm) | 125 | 125 | 125 | 125 | 125 | |

| Working layer number | 1(2) | 2 | 2 | 2 | 2(4) | |

| Plate unit pressure(Mpa) | 1.56 | 3.1 | 3.2 | 2.8 | 2.5 | |

| Piston stroke(mm) | 250 | 250 | 250 | 250 | 250(500) | |

| Motor power(kw) | 3.0 | 2.2 | 2.2 | 2.2 | 3.0 | |

| Overall dimension(mm) | L | 1200 | 1400 | 1650 | 1410 | 1900 |

| W | 400 | 550 | 600 | 680 | 950 | |

| H | 1300 | 1500 | 1600 | 1750 | 2000 | |

| Weight(kg) | 800 | 1300 | 1500 | 3500 | 6500 | |

Working Principle of O Ring Vulcanizing Equipment:

The working principle of O-ring vulcanizing equipment can be simply understood as “heating and pressurizing curing”. First, put the pre-treated raw rubber into the designed mold cavity. Then, put the mold between the heating plates of the equipment. The equipment applies huge pressure through the hydraulic system to close the mold tightly, and at the same time, the heating plate heats up rapidly and transfers heat to the mold and the rubber inside. Keeping at the set temperature and pressure for a certain period (i.e. vulcanization time), the rubber material undergoes a cross-linking reaction, and changes from the original soft and volatile state to a vulcanized rubber with high strength, high elasticity, heat resistance, chemical corrosion resistance and other characteristics, so that the O ring is formed and obtains the final performance.

O Ring Vulcanizing Equipment Customer Use and Evaluation:

- Case 1: A European seal manufacturer. The company mainly produces rubber seals for industrial pumps and valves. Their original vulcanizing equipment was inefficient, and the size consistency of the O-rings produced was poor, resulting in a high scrap rate. After introducing YG’s hydraulic vulcanizing machine, their production cycle was shortened by 30%, the size accuracy and physical property stability of the O-rings were significantly improved, and the scrap rate was reduced by 15%. A workshop manager said, “YG’s equipment is very stable and reliable, and it is also easy to operate. Now we can more confidently promise customers high-quality products and faster delivery.”

- Case 2: A North American automotive parts supplier. This company produces a variety of rubber parts for the automotive industry, including complex O-rings. They need vulcanizing equipment that can handle a variety of rubber materials and sizes and is easy to operate. After choosing YG’s o-ring vulcanizing equipment, they found that the mold replacement of the equipment was very convenient, making it efficient to switch between different products. Moreover, the equipment’s precise control of the vulcanization process ensures that each batch of O-rings meets the strict quality standards of the automotive industry. Their purchasing manager commented: “YG’s equipment is very cost-effective, the performance fully meets our needs, and the after-sales support is also very timely. This is a correct choice.”

Rubber Vulcanizing Machine Price and Purchase Information: Transparent and Competitive

The price of a rubber vulcanizing machine or other specific vulcanizing equipment (such as conveyor belt vulcanizing equipment) will vary greatly, and YG’s o-ring vulcanizing equipment price depends on factors such as the model, size, clamping force, degree of automation, and whether molds are included. As a manufacturer, YG Machinery provides factory-direct sales, which means you can get more competitive prices and enjoy more direct and professional pre-sales consultation and after-sales service. We recommend that customers contact us according to their specific production needs and budget to obtain a detailed quotation plan.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()