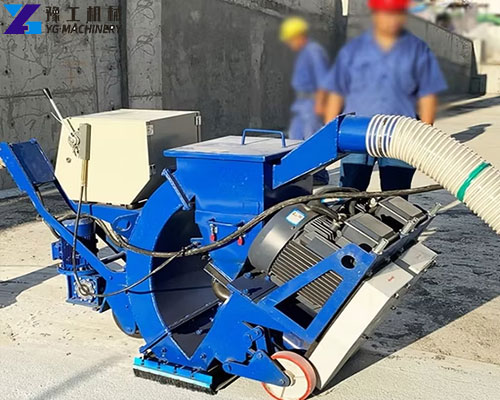

Looking for the most efficient road treatment equipment? YG road shot blasting machine is your answer! This machine is designed to quickly and thoroughly remove road contaminants, whether it is old coatings, oil stains, or concrete slurry. We use the strongest materials and the most advanced technology to build each machine to ensure that it can continue to operate efficiently under the most stringent working conditions. This means less downtime, higher output, and lower long-term operating costs. Contact us now for more product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Road Shot Blasting Machine Parameter

| Model | YG-270(Single) | YG550/600(Double) | YG-850(Double) | |

| Shot Blasting Wheel Diameter | 200mm | |||

| Working width | 270 mm | 550/600 mm | 800 mm | |

| Walking speed | 0.5~20 m/min | 0.5~33 m/min | ||

| Concrete surface cleaning efficiency | ≥180 m2/h | ≥400 m2/h | ≥600 m2/h | |

| Steel plate surface cleaning efficiency | 15-25 m2/h | 75-100 m2/h | 100-160 m2/h | |

| Dust connection pipe diameter | 120 mm

|

150 mm | ||

| Suggest the diameter of steel balls | 1.2-1.5 mm | 1.5-1.8 mm | ||

| Steel pill consumption | 10 g/m2 | |||

| Supporting the dust collector | Seven-core automatic backflush vacuum cleaner | Eight-core automatic backflush vacuum cleaner | ||

| Shot wheel motor | Power consumption | 11 kW | 11*2 kW | 15*2 kW |

| Input Current | ≤ 15 A | ≤ 22*2 A | ≤ 28*2 A | |

| Walking motor | Power consumption | 0.5 kW | 1.5 kW | |

| Input Current | 1 A | 3 A | ||

| Size (mm) | 1000*300*1100 | 1950*720/775*1400 | 1950*1020*1550 | |

| Weight | 150 kg | 570 kg | 700kg | |

| Power connection requirements | 400V, 50Hz, 100A, CEE socket | |||

Functional Features of YG Road Shot Blasting Machine

- Efficient processing capacity: YG floor shot blasting machine has powerful shot blasting capacity, a large one-time processing width, and efficiency far exceeds traditional manual grinding, greatly shortening the construction period.

- Deep cleaning and coarsening: It can thoroughly remove impurities such as pavement slurry, oil stains, coatings, etc., and form a uniform roughness on the surface, significantly improving the adhesion of subsequent coatings or materials.

- Accurate control system: Equipped with an intelligent control system, it can accurately adjust the shot blasting speed and steel shot flow to adapt to different road conditions and processing requirements.

- Environmental protection and energy-saving design: The integrated dust removal system effectively controls dust pollution and realizes dust-free construction; steel shots are recycled to reduce resource consumption.

- Modular design and easy maintenance: The main components adopt a modular design, which is easy to disassemble and assemble, and daily maintenance is simple and fast, reducing downtime.

- Wide applicability: Whether it is asphalt pavement, concrete pavement, or steel plate surface, this equipment can provide excellent processing results. It can easily handle various concrete floor bead blaster operations.

Cases of Thai and Korean Customers Using Road Shot Blasting Machines

Bangkok Expressway Bridge Deck Maintenance, Thailand

The expressway maintenance project in Bangkok, Thailand, faced a huge challenge: the old coating needed to be removed efficiently, and the bridge deck needed to be roughened. Traditional roughening methods are inefficient and dusty. Customer Mr. Somchai chose YG’s road shot blasting machine. He said, “YG’s equipment performed amazingly, greatly improving construction efficiency and compressing weeks of work into a few days. Most importantly, the efficient dust removal system ensured dust-free construction, which fully complied with environmental requirements. We are very satisfied with YG’s products and services.” The efficiency and environmental friendliness of YG’s equipment were highly praised in the busy urban project.

Busan Port Terminal Floor Renovation in South Korea

A damaged terminal floor at Busan Port in South Korea urgently needed to be renovated, requiring excellent anti-slip and wear-resistant properties. The floor needed to be thoroughly cleaned and roughened. Customer Mr. Kim finally chose YG’s heavy-duty floor shot blaster. He commented: “The YG pavement shot blasting machine is the secret weapon of the renovation project. It not only greatly shortens the construction period but also produces a high-quality rough surface and enhances the adhesion of the new anti-slip coating. YG’s products are very reliable, and the after-sales service response is fast. We are very satisfied.” YG equipment has demonstrated its powerful cleaning and roughening capabilities in large-scale, high-demand floor projects.

Why Choose YG Road Shot Blasting Machine?

- Extremely efficient: Say goodbye to the inefficiency of traditional methods! YG road shot blasting machine completes large-area cleaning at high speed, significantly shortening the project duration.

- Excellent quality: Ensures perfect roughening of the road or floor surface, greatly improving the adhesion and durability of subsequent coatings or materials.

- Environmentally friendly: Integrated efficient dust removal system to achieve dust-free construction, meet the most stringent environmental standards, and protect the health of workers.

- Easy to operate: Humanized design, easy to use and maintain, lowering the operating threshold.

- Wide application: From roads and bridges to airport runways and industrial floors, the YG road shot blasting machine can do everything. The flexible mobile road shot blasting machine meets various mobility needs, and the powerful floor shot blaster is suitable for large-area operations and is an ideal choice for a concrete floor bead blaster.

YG is your trusted partner. We not only provide high-quality equipment, but also provide comprehensive technical support and after-sales service. Choosing the YG road shot blasting machine means choosing the best balance of efficiency, quality, and environmental protection. Don’t hesitate, contact us now to get your customized solution.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()