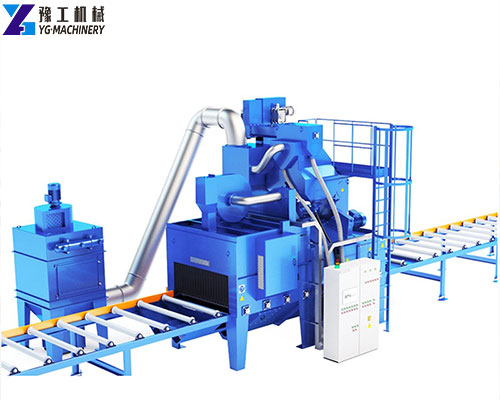

The YG steel shot blasting machine, also known as a steel shot blasting and cleaning machine or metal strengthening shot blasting machine, and commonly referred to as a steel shot blasting machine in the industry, is a specialized piece of equipment that uses steel shot as the abrasive medium to achieve rust removal, scale removal, deburring, and surface strengthening of workpieces through high-speed impact. Its main function is to use a high-speed rotating blasting wheel to precisely project steel shot or steel grit onto the workpiece surface, removing impurities and creating a certain degree of surface roughness through dense impacts. Whether it’s a massive bridge steel beam or a precision automotive part, if there is residual scale or rust on the surface, subsequent coatings will be at risk of peeling off. The YG steel shot blasting machine, designed specifically for metal workpieces, uses steel shot as the core abrasive medium, offering both precise cleaning and surface strengthening. It can be flexibly combined with sub-equipment such as roller conveyor shot blasting machines, and hanger-type shot blasting machines, adapting to both mass production and the processing of irregularly shaped workpieces. Contact us now for more product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

YG Steel Shot Blasting Machine Parameter

| Parameter | YG-698 | YG-6912 | YG-6915 | YG-6920 | YG-6925 | YG-6930 | YG-6940 |

| The effective cleaning

width(mm) |

800 | 1200 | 1500 | 2000 | 2500 | 3000 | 4000 |

| The room feed-in

size(mm) |

1000*400 | 1400*400 | 1700*400 | 2200*400 | 2700*800 | 3200*800 | 4200*400 |

| The length of cleaning

The workpiece (mm) |

1200-12000 | 1200-1600 | 1200-12000 | 1200-12000 | 3000-12000 | 2400-12000 | 4500-18000 |

| The speed of the conveyor

(m/min) |

0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| The thickness of the cleaning

steel sheet(mm) |

3-60 | 3-60 | 1.5-60 | 3-60 | 3-60 | 3-110 | 4.5-100 |

| The section steel

specification(mm) |

800*300 | 1000*300 | 1500*300 | 2000*300 | 2500*700 | 3000*700 | 4000*300 |

| The quantity of shot

blasting(kg/min) |

4*180 | 4*250 | 4*250 | 6*250 | 6*250 | 6*360 | 8*360 |

| The first enclosed

quantity(kg) |

4000 | 4000 | 4000 | 4500 | 4500 | 8000 | 11000 |

| Roll brush adjusting

height(mm) |

200 | 200 | 350 | 450 | 600 | 850 | 900 |

| Total power (kW) | 90 | 78.3 | 113.5 | 156.6 | 204.8 | 224.55 | 293.6 |

| Airness size(m3/h) | 22000 | 17560 | 19000 | 19550 | 27758 | 28050 | 38000 |

5 Advantages of the YG Steel Shot Blasting Machine

- Increased Product Lifespan and Reduced After-Sales Costs: The dual effect of surface strengthening and uniform cleaning enhances workpiece wear resistance and coating adhesion, preventing rust and coating peeling. Product lifespan is increased by an average of 30%, significantly reducing after-sales maintenance costs.

- Replaces Manual Labor and Improves Efficiency: The automated operation mode replaces 4-6 manual workers, increasing processing efficiency by 6-9 times compared to traditional manual methods. This significantly shortens production cycles and eliminates human error, ensuring consistent quality for batches of workpieces.

- Multi-Purpose Equipment, Increased Utilization: Adaptable to various workpieces and scenarios, eliminating the need to purchase separate equipment for single needs. Especially suitable for multi-product manufacturing companies. With dedicated accessories, it can also be used for road surface treatment, maximizing equipment utilization.

- Convenient Operation, Lower Labor Requirements: The intelligent control panel and visual parameter design allow ordinary operators to be trained and operational in 1-2 days, eliminating the need for specialized technical personnel and effectively reducing labor pressure and training costs for businesses.

- High Durability and Long-Term Cost-Effectiveness: Made with high-wear-resistant components and high-quality steel, the machine has a service life of 8-12 years under normal use. Low failure rate and comprehensive after-sales service make it more worry-free and economical in the long run.

3 Major Application Areas of YG Steel Shot Blasting Machines

- Steel Structure Manufacturing: Suitable for surface pretreatment of various types of steel, steel plates, and steel components. It can efficiently remove rust, scale, and welding residue from the surface of components while simultaneously strengthening the surface, improving the overall strength and corrosion resistance of the steel structure. This provides a high-quality surface foundation for subsequent painting and welding processes, ensuring the long-term stability of the steel structure. In this field, it can be combined with a roller conveyor shot blasting machine to achieve continuous operation of batch steel components, meeting the needs of large-scale production.

- Mechanical Parts Manufacturing: Covering various parts processing scenarios in automobiles, agricultural machinery, general machinery, etc., it can specifically process workpieces of different shapes, such as shafts, gears, bearings, and castings, completing multiple tasks such as deburring, descaling, and surface strengthening. By precisely adjusting the steel shot parameters, it can ensure the cleanliness of the parts’ surface while improving surface hardness and wear resistance, extending the service life of the parts, and meeting the production standards of high-precision mechanical products. It can be combined with a hanger-type shot blasting machine to process irregularly shaped parts.

- Transportation Engineering: Applicable to the construction and maintenance of transportation facilities such as roads, bridges, and tunnels. Its core applications include road surface strengthening, bridge steel component treatment, and tunnel steel support cleaning. With a road floor shot blaster attachment, it can strengthen the road surface, improving wear resistance and anti-slip properties, extending the service life of transportation facilities; it can also process bridge steel box girders, steel guardrails, and other components, ensuring the structural strength and corrosion resistance of transportation facilities, and is suitable for complex outdoor working environments.

Can Shot Blasting Replace Acid Pickling?

Shot blasting can replace acid pickling in most industrial applications—the core differences between the two lie in their process characteristics, environmental impact, and treatment effects. Acid pickling relies on chemical agents to corrode impurities on the metal surface. While it achieves high cleanliness, it generates a large amount of acidic wastewater, resulting in high environmental treatment costs and potential corrosion of the metal substrate, reducing workpiece precision. YG steel shot blasting machines, on the other hand, use a physical impact method, removing impurities through high-speed projection of steel shot. This process is free of chemical pollution, meeting environmental compliance requirements, and simultaneously strengthens the surface, improving the workpiece’s wear resistance. In terms of applicable scenarios, shot blasting can completely replace acid pickling in most metal surface pretreatment applications, such as steel structures, mechanical parts, and transportation facilities. Acid pickling remains suitable only for specific workpieces requiring ultra-high precision or extremely thin materials. Choosing YG equipment allows for a balance of environmental protection, efficiency, and strengthening requirements, avoiding the pollution and damage problems associated with acid pickling.

Steel Shot Blasting Machine Manufacturer – YG Machinery Factory

Whether it’s large-scale steel structure production, high-precision parts processing, or outdoor transportation facility maintenance, high-quality surface treatment is crucial for ensuring product quality. The YG steel shot blasting machine breaks through scene limitations with its flexible adaptability, and its chemical-free physical blasting technology meets today’s stringent environmental requirements while achieving both cleaning and strengthening objectives, completely solving the many pain points of traditional processes. To meet different production needs, YG also provides supporting products such as road floor shot blasters and hanger-type shot blasting machines, which can be flexibly combined according to workpiece type and operating scenario, enabling one-stop procurement and full-process adaptation. For companies pursuing production efficiency and product quality, choosing the YG steel shot blasting machine is not just adding a piece of equipment, but choosing a highly efficient and reliable surface treatment solution. Whether you need to process workpieces in batches or require customized solutions for irregularly shaped parts or outdoor scenarios, YG can provide a precise match. Contact us today to learn more about our products.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()