When undertaking foundation piling projects in city centers, near hospitals, or in sensitive areas, project contractors often face a significant dilemma: how to remove excess pile heads that exceed the design elevation after the piles are driven? Using manual sledgehammers or pneumatic breakers for removal results in massive noise and dust pollution, easily leading to complaints from nearby residents and even project halts. More seriously, this impact-based breaking method easily creates micro-cracks invisible to the naked eye within the pre-existing pile section, causing permanent damage to the pile’s bearing capacity and structural durability.

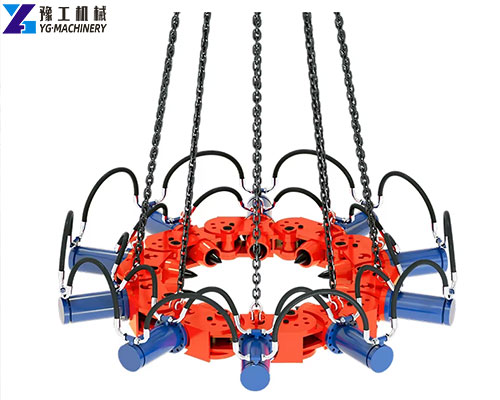

The YG excavator pile breaker, through a precisely controlled hydraulic system, applies powerful static pressure evenly around the pile head, causing the concrete to naturally break and peel off at the predetermined section. The entire process is quiet, vibration-free, and dust-free. As a highly efficient hydraulic pile breaker, it not only increases pile cutting efficiency by more than ten times but also fundamentally ensures the structural integrity of the pre-existing pile section. Choosing YG means your project can complete pile cutting quickly and quietly, while achieving the highest engineering quality assurance and optimal social benefits. Contact us now for more product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Excavator Pile Breaker Parameter

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| A combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.

Cylinder required |

20L/min | Machinery Tonnage | ≥20T | Location pin

Φ35 |

|||||||

| Max.

Cylinder Trip |

300mm | Chisel diameter | 110mm | Single

module weight |

335KG | ||||||||

| Max.

Cylinder Pressure |

300MPa | Max.

Hoist Capacity |

≤500mm | Single

module size |

1015*865*340mm | ||||||||

YG Excavator Pile Breaker Core Functions and Technical Features

- Non-destructive Static Pressure Crushing: Utilizes static compression rather than impact crushing, ensuring the pre-existing pile section is free from vibration damage or micro-cracks, resulting in higher pile foundation quality.

- Modular Design and High Versatility: Modular jaws can be quickly added or removed, easily adapting to round piles from 300 mm to 1800 mm in diameter, or square piles of varying side lengths.

- Extremely High Operational Efficiency: Removing a pile head typically takes only 1 to 5 minutes, more than 10 times more efficient than manual chiseling.

- Environmentally Friendly and Low-Noise: The entire process is impact-free, low-noise, and produces minimal dust, making it ideal for construction projects in city centers, near hospitals, or residential areas.

- Intact Reinforcing Steel Protection: The broken concrete blocks naturally separate from the reinforcing steel, leaving it intact and vertical, facilitating subsequent structural connections and cleanup.

Customers in Dubai and Malaysia Used YG’s Pile Breakers to Complete Projects

Case Study 1: Dubai Viaduct Foundation Project, UAE

- Client Background: A large infrastructure contractor in Dubai was responsible for the multi-pile foundation project of a viaduct in the city’s core area, requiring the removal of a large number of pile heads within a very short timeframe.

- Problem Solved: Low worker efficiency in high temperatures, and the client demanded minimal construction noise to comply with urban regulations. Traditional crushing methods were unacceptable.

- Product Used: YG Modular Excavator Pile Breaker (compatible with 25T excavators).

- Results: The client used this hydraulic pile breaker, achieving the removal of one pile head within 1 minute. The static pressure operation fully met low-noise requirements. The significant increase in efficiency allowed the foundation project to be completed 10 days ahead of schedule.

- Client Testimonial: “YG’s excavator pile breaker is like the ‘Tesla’ of pile cutters! Highly efficient, quiet, and most importantly, it ensured the integrity of our pile structure, which is our highest pursuit of quality.”

Case Study 2: Pile Foundation Engineering for a Residential Project in Kuala Lumpur, Malaysia

- Client Background: A medium-sized residential developer in Malaysia needed to handle 400 600mm circular piles and wanted to recycle the crushed concrete.

- Problem Solved: Improving pile cutting efficiency while finding an economical and environmentally friendly solution for concrete waste disposal.

- Products Used: YG excavator pile breaker in conjunction with a YG excavator crusher bucket.

- Results: The concrete pile cutter quickly and in batches cut off the pile heads. The separated concrete blocks were then gripped by an excavator and crushed on-site using the excavator crusher bucket, directly used as backfill aggregate. This achieved a closed-loop operation of pile cutting and waste recycling.

- Client Testimonial: “Using YG’s combined equipment, we not only solved the pile cutting problem but also turned construction waste into usable aggregate, saving a significant amount of transportation and landfill costs. The investment in this excavator pile breaker was absolutely worthwhile!”

How Can the Hydraulic Pile Breaker Be Used in Conjunction with the Excavator Crusher Bucket to Achieve On-Site Crushing and Recycling of Construction Waste?

The excavator crusher bucket is a key tool for on-site recycling of construction waste, greatly simplifying the previously complex crushing process and integrating it directly onto the excavator.

Firstly, in foundation engineering, after using an excavator pile breaker to cut the pile head, a large number of concrete blocks of varying sizes are generated. Traditionally, these concrete blocks need to be transported by truck to specialized waste disposal sites, incurring high transportation and landfill costs and causing environmental pollution.

To achieve on-site recycling, the excavator simply needs to detach the pile breaker and quickly install the excavator crusher bucket. This crusher bucket works like a mobile jaw crusher: the excavator directly grabs the concrete blocks generated after pile cutting or the brick and stone waste from on-site demolition using the crusher bucket, feeding them into the crushing chamber inside the bucket. A hydraulic system drives the jaw plates to powerfully crush the large pieces of waste into small particles of predetermined dimensions.

By adjusting the discharge port of the crushing hopper, the construction team can control the final aggregate particle size, generating recycled aggregate suitable for different applications. For example, coarse particles can be immediately used for paving temporary roads or backfilling site foundations; fine particles can be used for site leveling. This “produce and use as needed” closed-loop operation mode not only completely eliminates the costs of waste transportation and landfilling, but also transforms construction waste into valuable resources, greatly improving the economic benefits and environmental protection level of the project, making it the most effective means to achieve modern green construction sites.

Buy YG Excavator Pile Breaker – Factory Price

After gaining a thorough understanding of the superior performance and static crushing advantages of the YG excavator pile breaker, we hope you recognize that the value this equipment brings goes far beyond its physical form. It represents a steadfast commitment to project quality and an ultimate pursuit of construction efficiency. Micro-cracks left in the pile body by traditional pile cutting methods are the biggest hidden danger to future structural safety. YG’s hydraulic pile breaker, through the principle of synchronous static pressure, fundamentally eliminates this structural damage, ensuring the integrity and reliability of your pre-reserved pile foundation section.

As your long-term partner, the YG Group provides support beyond the equipment itself. We understand that efficient construction requires a comprehensive service system. Therefore, we are committed to providing all our customers with comprehensive technical support and after-sales service. This includes customized configuration modules based on your specific pile type (round or square), providing precise installation guidance and operational training to ensure your operators can quickly and skillfully master the use of this concrete pile cutter. Choosing the YG excavator pile breaker is not just investing in an advanced excavator attachment, but also introducing a reliable, efficient, and experienced quality control expert to your project.

Contact YG’s team of foundation engineering solutions experts now. Simply provide your pile diameter, pile type, and excavator model, and we will immediately develop the optimal excavator pile breaker configuration for you. Contact us today!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()