Still struggling with tedious manual tapping and inefficient semi-automatic equipment? It’s time to upgrade your production line! The YG automatic thread tapping machine is a powerful tool that simplifies and enhances the efficiency of thread processing. It’s easy to operate, and with just one button, you can start fully automatic tapping. Our equipment offers exceptional stability and durability, enabling trouble-free operation around the clock, allowing you to run your production line at full capacity. This fully automatic tapping machine is not only fast but also highly precise, producing smooth, standard threaded holes that perfectly meet your quality requirements. More importantly, it significantly reduces reliance on manual labor, saving labor costs and effectively reducing tool wear and material waste caused by improper operation. Choosing YG means choosing higher efficiency, lower costs, and more stable quality. Let your production line bid farewell to inefficiency and enter the era of automation. Contact us now.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Automatic Thread Tapping Machine Parameter — Support Customization

| Specification | YG-20/40 | YG-25/50 | YG-30/60 |

| Tapping capacity in steel | 6-20mm coarse pitch, 6-40mm fine pitch | 6-25mm coarse pitch, 6-50mm fine pitch | 10-30mm coarse pitch, 10-60mm fine pitch |

| Spindle diameter | 30mm | 35mm | 40mm |

| Spindle travel max. | 110mm | 110mm | 125mm |

| Column diameter | 100mm | 100mm | 110mm |

| Distance between b/w spindle center and to column | 216mm | 216mm | 250mm |

| Table shape | Rectangular | Rectangular | Square |

| Table size (lxb) | 405x225mm | 405x225mm | 760x590mm |

| Working area | 330x150mm | 330x150mm | 620x260mm |

| Floor area(lxb) | 1220x760mm | 1220x760mm | 1400×620 |

| No. Of speeds | 2 AC drive optional | 2 AC drive optional | AC Driver |

| Motor required | 2 HP/1440 rpm | 2 HP/1440 rpm or 2 HP/900rpm | 3 HP/1440 rpm |

| Total height | 1900mm | 1900mm | 2100mm |

| Total weight | 350kg.(approx) | 400kg.(approx) | 550kg.(approx) |

| Max. Tap shank that can be held in the tap holder | 20mm | 30mm | 40mm |

| Complete belt cover | YES | YES | YES |

| Motor cover within the machine frame | YES | YES | YES |

| Coolant system | YES | YES | YES |

| Counter meter | YES | YES | YES |

| Safety cut-off limit switches | YES | YES | YES |

| Phase preventer | YES | YES | YES |

| Coolant tank capacity | 40 Liters | 40 Liters | 40 Liters |

| Various pitch sizes can be done | METRIC PITCH 0.8,1.0,1.25,1.5,1.75, 2.0,2.5 UNIFIED PITCH(tpi) 26,24,20,19,18,16,14 12 | METRIC PITCH 1.0,1.25,1.5,1.75, 2.0,2.5,3.0,3.5 UNIFIED PITCH(tpi) 24,20,19,18,16,14 12,11 | METRIC PITCH 1.0,1.25,1.5,1.75, 2.0,2.5,3.0,3.5,4.0 UNIFIED PITCH(tpi) 24,20,19,18,16,14 12,11,10,8 |

| Standard equipment | Floating tap holder 2no., 2no. Tap collets of any size, 2no. Lead screw (fitted), spanners, ln keys | Floating tap holder 2no., 2no. Tap collets of any size, 2no. Lead screw (fitted), spanners, ln keys | Floating tap holder 2no., 2no. Tap collets of any size, 2no. Lead screw (fitted), spanners, ln keys |

Working Principle of a Fully Automatic Tapping Machine

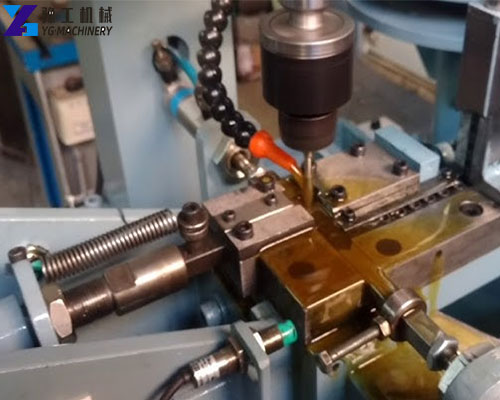

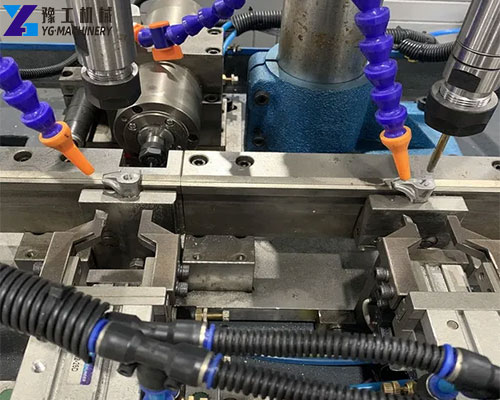

After the workpiece is secured in a fixture, the operator selects a preset machining program via the touchscreen. Driven by a servo motor, the machine’s spindle rotates the tap at the set speed and torque. When the tap contacts the workpiece, the control system precisely controls the feed rate, allowing the tap to enter the hole along a predetermined trajectory and cut the internal thread. When the set depth is reached, the spindle reverses, the tap withdraws, and a standard threaded hole is completed. The entire process is precisely controlled by the automatic tapping machine, requiring no human intervention.

Applications of YG Automatic Tapping Machines

- Automotive Parts Manufacturing: Used for threading key components such as engine blocks, transmission housings, and wheel hubs.

- Electronic Product Housings: Precision tapping ensures accurate screw holes in housings of mobile phones, computers, and household appliances.

- Hardware and Bathroom Industry: Widely used for threading faucets, valves, pipe fittings, and other products.

Our automatic nut-tapping machine, in particular, is designed specifically for high-speed, mass-produced nut production, offering exceptional efficiency.

Automatic Thread Tapping Machine Manufacturer – YG Machinery

After a comprehensive review, we can conclude that choosing YG’s automatic thread tapping machine is more than just purchasing a piece of equipment; it’s an investment in an efficient, reliable, and intelligent solution for your production line. With its superior automation capabilities, this machine easily handles a variety of complex thread processing tasks, transforming traditional manual operations into precise, fast, automated processes. It not only significantly improves production efficiency, doubling your production capacity, but also effectively reduces defective products and material waste through precise control, saving your company considerable operating costs.

For manufacturers striving for product quality and production efficiency, YG’s fully automatic tapping machine is undoubtedly a powerful engine for business growth. Its easy operation and low maintenance ensure stable service on your production lines, ensuring high-quality threads on every product. When you see workpiece after workpiece being precisely and efficiently processed, you’ll realize that this machine brings more than just threaded holes; it also brings peace of mind and trust. If you’re looking to upgrade your equipment or are looking for a more efficient thread processing solution, then it’s time to consider YG’s automatic thread tapping machine. It will help you stand out in the fiercely competitive market and create greater value for your business. Contact us now.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()