Hot-sale Tapping Machine Technical Parameter

| SPECIFICATION | YG-20/40 | YG-25/50 | YG-30/60 |

| TAPPING CAPACITY IN STEEL | 6-20mm coarse pitch, 6-40mm fine pitch | 6-25mm coarse pitch, 6-50mm fine pitch | 10-30mm coarse pitch, 10-60mm fine pitch |

| SPINDLE DIAMETER | 30mm | 35mm | 40mm |

| SPINDLE TRAVEL MAX. | 110mm | 110mm | 125mm |

| COLUMN DIAMETER | 100mm | 100mm | 110mm |

| DISTANCE B/W SPINDLE CENTER TO COLUMN | 216mm | 216mm | 250mm |

| TABLE SHAPE | Rectangular | Rectangular | Square |

| TABLE SIZE (LxB) | 405x225mm | 405x225mm | 760x590mm |

| WORKING AREA | 330x150mm | 330x150mm | 620x260mm |

| FLOOR AREA(LxB) | 1220x760mm | 1220x760mm | 1400×620 |

| NO. OF SPEEDS | 2 AC Drive Optional | 2 AC Drive Optional | AC Driver |

| MOTOR REQUIRED | 2 HP/1440 rpm | 2 HP/1440 rpm Or 2 HP/900rpm | 3 HP/1440 rpm |

| TOTAL HEIGHT | 1900mm | 1900mm | 2100mm |

| TOTAL WEIGHT | 350kg.(approx) | 400kg.(approx) | 550kg.(approx) |

| MAX. TAP SHANK THAT CAN BE BEHOLD IN THE TAP HOLDER | 20mm | 30mm | 40mm |

| COMPLETE BELT COVER | YES | YES | YES |

| MOTOR COVER WITHIN MACHINE FRAME | YES | YES | YES |

| COOLANT SYSTEM | YES | YES | YES |

| COUNTER METER | YES | YES | YES |

| SAFETY CUT-OFF LIMIT SWITCHES | YES | YES | YES |

| PHASE PREVENTER | YES | YES | YES |

| COOLANT TANK CAPACITY | 40 Liters | 40 Liters | 40 Liters |

| VARIOUS PITCH SIZES CAN BE DONE | METRIC PITCH 0.8,1.0,1.25,1.5,1.75, 2.0,2.5 UNIFIED PITCH(tpi) 26,24,20,19,18,16,14 12 | METRIC PITCH 1.0,1.25,1.5,1.75, 2.0,2.5,3.0,3.5 UNIFIED PITCH(tpi) 24,20,19,18,16,14 12,11 | METRIC PITCH 1.0,1.25,1.5,1.75, 2.0,2.5,3.0,3.5,4.0 UNIFIED PITCH(tpi) 24,20,19,18,16,14 12,11,10,8 |

| STANDARD EQUIPMENT | Floating Tap holder 2no., 2no. Tap collets of any size, 2no. Lead Screw (Fitted), spanners, LN keys | Floating Tap holder 2no., 2no. Tap collets of any size, 2no. Lead Screw (Fitted), spanners, LN keys | Floating Tap holder 2no., 2no. Tap collets of any size, 2no. Lead Screw (Fitted), spanners, LN keys |

- The automatic tapping machine will not have broken wires and missing tapping. It is not easy to damage the wiretap. If there is any doubt, the equipment will actively alarm and stop.

- The automatic tapping machine is customized according to the customer’s sample plan, with good stability, high power, high precision, fast speed, low investment, and a short cost recovery period.

- The automatic tapping machine works stably, maintenance and repair are more convenient, the failure rate is extremely low, and the power consumption of the equipment is low. This equipment can be shared by a variety of similar products.

- It is easy to replace the workpiece with an automatic tapping machine. It only needs to change the disc mold and the clamping material. Because the main machine is inclined, the tapping chips are easily cleaned, and the cutting oil can deepen the workpiece and achieve the best smoothness.

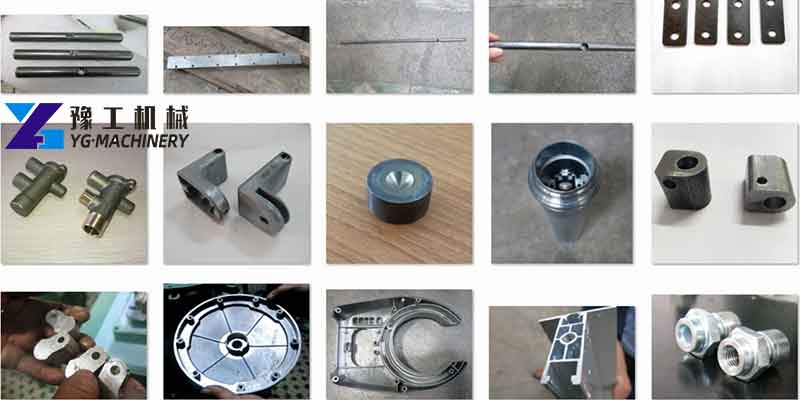

- Hardware processing products, precision parts for cars, electronics, special-shaped nuts, rivets, rivet nuts, etc.

- This equipment is mainly aimed at threading pins, rivet nuts, connecting shafts, short shaft parts, sleeves, valve cores, grinding head rods, small pipe fittings, and various non-standard hardware car parts inner hole tapping processing, blind holes can be processed The fixture can be flexibly replaced with through-hole products and can be used for tapping processing of workpieces with different shapes.

Automatic Tapping Machine Price – YG Machinery Manufacturer

The automatic tapping machine has a high degree of automation. When working, as long as the part blank is put into the hopper, it can automatically feed, position, clamp, excavate, and unload. A worker can operate multiple devices at the same time. High production efficiency, can greatly save labor costs. A high-quality tapping machine has the characteristics of novel design, reasonable structure, convenient use, high degree of automation, easy to use, high efficiency, maintenance-free, cost-effective, and so on. And this machine can enjoy 10% off. In addition, we also have other production lines, such as disposable cup-making machines, paper bowl-making machines, paper dish-making machines, paper straw-making machines, etc. If you are interested in these machines, please contact us ASAP.