In the competitive plastics market, every manufacturer is searching for the most cost-effective production tools. For companies purchasing blow molding machines, they need more than just a low price; they need a partner who can guarantee long-term, stable production. As a veteran blow molding machine manufacturer, YG understands the delicate balance between performance and price. We don’t blindly pursue low prices at the expense of quality, nor do we blindly pile on high-end features and push up the investment threshold for our customers. Our goal is to provide the most suitable solutions for customers with diverse needs. A qualified blow molding machine is more than just a tool; it’s your factory’s most valuable asset. It must reliably and quickly transform plastic raw materials into the bottles, cans, and buckets we see everywhere in our daily lives. Inefficient machines or defects in the bottles they produce can significantly increase production costs. YG’s series of plastic blow molding machines is designed to address these pain points. We understand that you need more than just a single number; a clear value analysis is essential. Contact us now to discuss factors that influence the price of a blow molding machine, such as whether to choose a PET bottle blowing machine specifically for beverage bottles or an injection blow molding machine capable of producing more complex containers. Our goal is to help you clearly understand how to obtain efficient, durable blow molding equipment that will generate long-term profits within your budget. Contact us for more professional information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

YG Blow Molding Machine Parameter

| Main Parameters | Unit | YG100-90L |

| Max. Product Volume | (L) | 90 |

| Dry Cycle | (pcs/h) | 360 |

| Screw Diameter | (mm) | 100 |

| Screw L/D Ratio | (L/D) | 25 |

| Screw Drive Power | (KW) | 45 |

| Screw heating Power | (4ΦKW) | 24 |

| Screw Heating Zone | (Zone) | 4 |

| HPDE Output | (kg/h) | 180 |

| Oil Pump Power | (KW) | 22 |

| Clamping Force | (KN) | 500 |

| Mold Stroke | (mm) | 550-1250 |

| Max. Mold Size | (W×H)(mm) | 800×1000 |

| Accumulator Capacity | (L) | 12 |

| Max. Die Diameter | (mm) | 430 |

| Die Heating Power | (4ΦKW) | 20 |

| NO. of Heating Zones | (Zone) | 5 |

| Blowing Pressure | (MPa) | 0.8 |

| Air Consumption | (M3/min) | 1.2 |

| Cooling Water Pressure | (MPa) | 0.3 |

| Water Consumption | (L/min) | 100 |

| Machine Size | (L×W×H)(m) | 5.4×2.5×4 |

| Machine Weight | (Ton) | 16 |

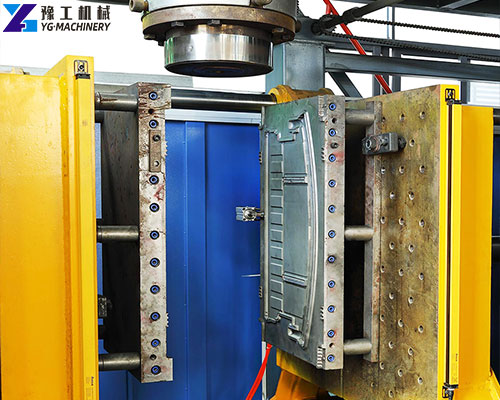

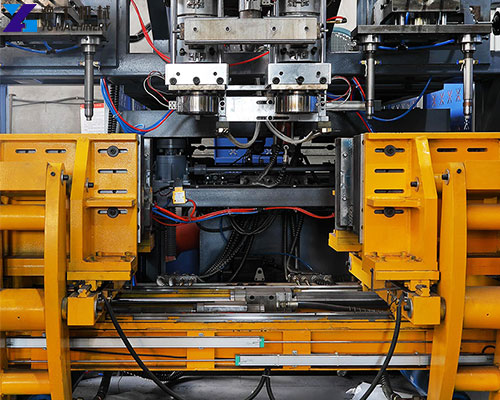

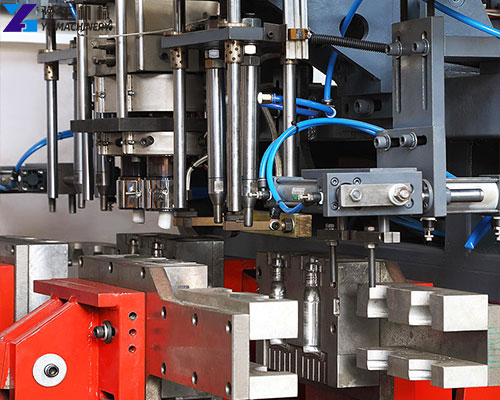

YG Plastic Blow Moulding Machine Features

- Multi-Material Adaptive Production: Compatible with a variety of plastic materials, including PET, PE, PP, and PVC, this machine can produce 50ml-5L plastic bottles and cans. Compared to dedicated PET bottle blowing machines, it offers a wider range of applications, meeting the diverse production needs of businesses.

- High-Efficiency Molding Technology: Utilizing a combined “rapid extrusion + high-pressure blowing” process, this machine achieves a single production cycle of just 15 seconds and an hourly output of up to 240 500ml PET bottles (for example), representing a 25% increase in efficiency over traditional equipment.

- Intelligent Temperature Control System: Eight independent heating coils, coupled with a PID temperature control algorithm, precisely control the barrel temperature in different sections, preventing overheating and decomposition of the plastic material. This ensures a consistently high molded product yield exceeding 99.5%.

- Energy-Saving Design: The motor utilizes variable frequency speed regulation, automatically switching to low speed when not in production. The heating system is equipped with insulation, reducing heat loss by 30%, resulting in an hourly power consumption of only 8.5 kWh, well below the industry average of 12 kWh.

- Convenient Mold Change: The quick-release mold mounting structure eliminates the need to disassemble numerous components when changing molds of different specifications, reducing mold change time to under 30 minutes and minimizing equipment downtime.

- Safety Features: The machine is equipped with an emergency stop button, an infrared hand guard, and an overload protection system. Automatic shutdown occurs when the operator’s hand approaches the mold clamping area or the machine is overloaded. Operating noise is controlled below 75dB, meeting workshop environmental requirements.

Use Cases and Evaluations of Yugong Machinery’s Blow Molding Machines in Different Countries, Such as Brazil and Saudi Arabia

Case 1: Saudi Arabian Beverage Manufacturing Giant

- Client Background: A large Saudi beverage group sought a high-capacity PET bottle blowing machine to meet the huge summer demand for drinking water.

- Problem Solved: The old equipment consumed a lot of energy and had a high failure rate in high-temperature environments.

- Results: The client purchased a high-speed, fully automatic 8-cavity blow molding machine from YG. Even in a workshop with a year-round 45°C temperature, the equipment maintains an extremely low failure rate, maintains stable production capacity, and meets design specifications. Its energy-saving features save the client tens of thousands of dollars in electricity costs annually.

- Client Comment: “We compared the price and performance of several blow molding machine manufacturers. Although the initial price of YG’s equipment was slightly higher, its stability and excellent energy efficiency paid for itself in less than six months, making it a very worthwhile investment.”

Case 2: Brazilian Pharmaceutical Packaging Company

- Client Background: A Brazilian company specializing in pharmaceutical and healthcare product packaging needed to produce high-precision HDPE bottles.

- Product Used: YG injection blow molding machine.

- Results: This injection blow molding machine achieves high-precision, integrated molding of the bottle neck and body, eliminating the uneven neck cuts associated with traditional extrusion blow molding. The finished container’s sealing performance far exceeded customer expectations and successfully passed the rigorous testing of the National Medical Products Administration.

- Customer Comment: “YG’s injection blow molding machine has helped us enter the high-end pharmaceutical packaging market. It features a high degree of automation, simple operation, and meets our highest quality standards.”

Blow Molding Machine Price – YG Machinery Manufacturer

When searching for a suitable plastic blow molding machine, I understand you may have many questions and concerns, especially regarding price transparency. The chaotic pricing in the market can be confusing. I assure you that every quote from YG is open, fair, and detailed. We won’t hide any extra costs, and we’ll clearly explain why our machines are worth the price and how their high efficiency and low energy consumption will provide a long-term return on your investment.

You may be worried about operating such a complex machine. Our pet bottle blowing machines feature an intuitive, intelligent control system, ensuring even first-time workers can quickly master them with our professional training. We believe the best technology should be the easiest to use. As a responsible blow molding machine manufacturer, our service doesn’t end with your payment. We promise responsive after-sales support and a sufficient supply of spare parts to keep your production line running smoothly. Whether you choose an injection blow molding machine or another model, you’re buying with peace of mind and reliability. We don’t make you feel like you’re gambling, but rather like you’re making a sound investment. Please call our customer service hotline or email us to discuss your needs. I’ll arrange for a free online consultation with my team of professional engineers. We’ll analyze your production needs in detail and provide a clear, reliable blow molding machine price list to maximize efficiency and profitability for your business. Contact us now.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()