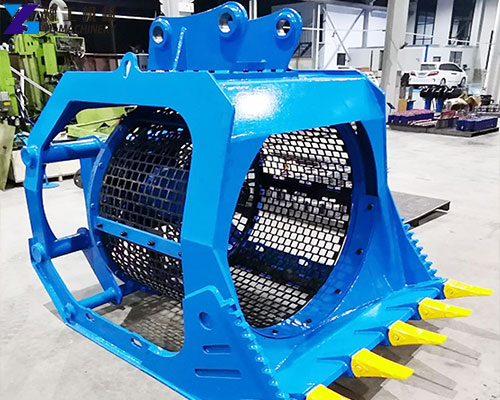

In municipal maintenance, courtyard renovation, and small-scale mining, mini excavators have become core equipment due to their flexibility and convenience, and the performance of specialised attachments directly determines operational efficiency. The mini excavator screening bucket, a core attachment for screening materials in small-scale projects, can quickly separate materials such as sand, soil, and construction waste, eliminating the need for additional screening equipment and significantly simplifying the construction process. YG, deeply involved in the R&D of mini excavator attachments, has created the mini excavator screening bucket, which is not only compact and highly adaptable but also works in conjunction with equipment such as the excavator quick hitch and excavator orange peel grapple, perfectly solving the pain points of “low screening efficiency and difficulty in material separation” in small-scale projects. It has become a cost-effective choice for municipal, landscaping, and small-scale mining industries, adapting to the needs of small-scale construction projects worldwide. Contact us now for more product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Mini Excavator Screening Bucket Parameter

| Model Number | Applicable Tonnage of Excavator(T) | Operating Flow(L/min) | Working Pressure(Mpa) | Self Weight(Kg) | Number of Revolutions Per Minute(RPM) |

| YG01 | 1.5-3 | 20 | 10-12 | 158 | 35 |

| YG02 | 3.5-5.5 | 30 | 10-12 | 245 | 60 |

| YG08 | 6-10 | 45 | 12-15 | 530 | 65 |

| YG012 | 11-18 | 65 | 15-18 | 1020 | 65 |

| YG016 | 19-28 | 80 | 18-22 | 1920 | 65 |

| YG018 | 29-38 | 150 | 18-22 | 2430 | 65 |

Check the Features of the Excavator Screening Bucket

- Lightweight and Adaptable Design: Customizable for excavators, with a wide range of applications. Its lightweight and compact size minimises equipment load and ensures excavator operational stability.

- Integrated Screening and Crushing: Built-in rotating screen and crushing teeth allow material to be screened by the rotating screen after entering the bucket, while the crushing teeth break down small, hard materials.

- Multi-Aperture Screen Options: Equipped with detachable screens of various aperture sizes, allowing for replacement based on material type (sand, soil, construction waste) to meet different screening precision requirements.

- Quick-Change and Collaborative Compatibility: Compatible with the excavator quick hitch for quick attachment changes and switching between screening, excavation, and grabbing modes; also compatible with the excavator orange peel grapple for direct grabbing of screened material, improving process efficiency.

- Wear-Resistant and Durable Structure: The bucket and screen are made of high-strength wear-resistant steel, with reinforcing strips added to the screen edges to prevent deformation due to material impact and extend service life.

- Simple and convenient operation: No external power source is required. The screen rotation is driven by the hydraulic system of the mini excavator itself, and the speed can be adjusted by the operating handle. Ordinary operators can learn to operate it after simple training.

Case Studies of Customers in Germany and Australia Using YG Screening Bucket

Case Study 1: A German Municipal Engineering Company

- Client Background: This company primarily undertakes small-scale municipal projects such as urban road maintenance and pipeline laying. Traditional manual sand and gravel screening is inefficient, and small excavators lack dedicated screening attachments, resulting in slow construction progress.

- Product Used: YG mini excavator screening bucket (compatible with 5-ton small excavators)

- Solutions: On-site sand and gravel screening by the equipment eliminates the need for manual assistance. Combined with the excavator quick hitch, it allows for rapid switching between excavation and screening modes, significantly improving the efficiency of roadbed backfilling.

- Results: Single project construction time is reduced by 30%, labour costs are reduced by 50%, and the purity of the screened sand and gravel fully meets municipal engineering standards.

- Customer Testimonial: “YG’s mini excavator screening bucket is a perfect fit for our small excavator. It’s easy to operate and highly efficient. Combined with the rock crusher bucket for crushing small stones, one machine solves both screening and crushing problems. Direct from the manufacturer, the price is reasonable, and the after-sales service is prompt. It has become an essential accessory for our municipal projects.”

Case Study 2: A Small Landscaping Company in Australia

- Client Background: The company specialises in courtyard renovation and landscape construction. They frequently need to screen soil and separate sand and gravel. Traditional screening methods are time-consuming and labour-intensive, impacting project delivery cycles.

- Products Used: YG mini excavator screening bucket (compatible with a 3-ton small excavator) + excavator orange peel grapple

- Solutions Solved: The equipment quickly screens planting soil, removing impurities. The screened sand and gravel can be used for courtyard paving. Combined with the grab bucket, it facilitates seedling transplantation, resulting in a smooth and efficient process.

- Results: Courtyard renovation projects have seen an average 25% reduction in construction time, significantly improved customer satisfaction, and the equipment is highly durable and has operated without failure for a long time.

- Customer review: “This mini screening bucket has completely changed our work. The lightweight design doesn’t burden the mini excavator, and screen replacement is very convenient. Switching attachments with the excavator quick hitch only takes a few minutes, and using it with the excavator orange peel grapple makes the entire process from soil screening to seedling planting highly efficient. It’s the ideal equipment for small-scale landscaping projects!”

Mini Excavator Screening Bucket Manufacturer – YG Machinery Factory Price

The YG mini excavator screening bucket, with its lightweight design, integrated screening and crushing capabilities, and multi-scenario compatibility, has become a cost-effective accessory for small-scale engineering projects. It not only solves the pain points of low screening efficiency and high costs in traditional small-scale projects but also works in conjunction with equipment such as the excavator quick hitch and excavator orange peel grapple to form a complete solution for small-scale engineering operations. Whether it’s municipal maintenance, landscaping renovation, or small-scale mining, this equipment can help projects progress with its high efficiency, convenience, and economy. Currently, the product has been exported to many countries and regions worldwide and has gained widespread recognition from overseas customers. If you are looking for a high-efficiency screening accessory for mini excavators, please contact YG’s official customer service immediately for the latest mini excavator screening bucket model configurations, detailed guidance on screen size selection, and customised quotes. Also, inquire about our bundled purchasing options for the excavator orange peel grapple and rock crusher bucket to create greater value!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()