As an experienced engineer, I know that it is not easy to cut thick concrete walls quickly and accurately on construction sites. Traditional cutting methods are not only inefficient but also often come with considerable safety hazards, dust, and a harsh working environment. But now, I would like to introduce you to YG’s remote-controlled wall saw, which has completely changed the way I work! This machine is like an efficient smart assistant to me. It allows me to control the cutting process precisely from a distance with the remote control, and I no longer have to go near those dangerous areas. It can cut various concrete walls very accurately, making construction fast and safe, and greatly reducing dust. Contact YG now for more product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Remote-Controlled Wall Saw Parameter

| Hydraulic

Oil

Pump |

Model | YG 600 | YG 700 |

| Max. power | 25KW | 30KW | |

| Motor cooling method | Air cooling | water cooling | |

| Rated voltage | 380V 50HZ | 380V-420V 50HZ-60HZ | |

| Pressure stages | 3 | 3 | |

| Max.. operating pressure | 200bar/20Mpa | 210bar/21Mpa | |

| Oil flow rate | 30-80L/min | 40-100L/min | |

| Dimensions | 600mm*650mm*1050mm | 500mm*520mm*1100mm | |

| Weight | 220kg | 140kg | |

| Wall

Saw |

Saw blade diameter range | 800-1400mm | 800-1600mm |

| Cutting depth | 620mm | 730mm | |

| Max.. working pressure | 180bar/18Mpa | 200bar/20Mpa | |

| Max.. oil flow rate | 100l/min | 100l/min | |

| Gearing | Gear | Gear | |

| Rotation speed | 450/950/1300Rpm | 450/850/1200Rpm | |

| Dimension | 400mm*420mm*400mm | 400mm*420mm*400mm | |

| Weight | 38kg | 39kg |

Remote-Controlled Wall Saw for Sale

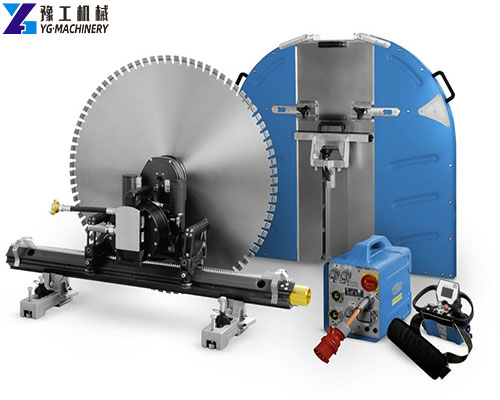

YG remote-controlled wall saw is a well-designed and high-performance concrete cutting equipment. Its main structure is sturdy and durable, mainly made of high-strength alloy materials, ensuring stable operation even in harsh construction environments. The core components of the equipment include the drive motor, saw blade mounting system, guide rail system, and the most critical remote control unit.

The drive motor provides powerful power, usually using hydraulic or high-frequency motors, to ensure that the saw blade can cut into hard concrete at high speed and stably. The saw blade mounting system is well designed, and saw blades of different diameters can be quickly replaced to meet the needs of different cutting depths and materials. The guide rail system is the key to achieving precise cutting. The saw body moves precisely along the pre-installed guide rails to ensure a straight and smooth cutting track.

The remote control unit is the highlight of this equipment, which allows the operator to accurately control various functions of the equipment, such as cutting speed, feed depth, and saw blade direction, from a safe distance. This design not only greatly improves construction safety, but also liberates operators to monitor the cutting process more flexibly.

Working Principle of Hydraulic Wall Cutting Saw Machine

The working principle of the YG remote-controlled wall saw is relatively intuitive but highly technical. It mainly drives the diamond saw blade to rotate at high speed through a hydraulic or high-frequency motor drive system. The saw blade is installed on a saw body that can slide along a guide rail pre-fixed on the wall.

The operator issues instructions to control the start, stop, rotation direction, and speed of the saw blade motor through a wireless remote control. At the same time, the remote control can also control the feed speed and cutting depth of the saw body. The hydraulic system or electric screw system is responsible for pushing the saw body to move precisely along the guide rail to ensure that the saw blade cuts into the concrete at a constant speed and pressure.

The cutting process is usually accompanied by a water cooling system. The cooling water is sprayed directly onto the saw blade and the cutting surface through a nozzle to cool the saw blade, lubricate the cutting surface, and suppress dust. All these operations are carried out under the remote monitoring of the operator, avoiding the risk of the operator being directly exposed to a dangerous environment in traditional cutting methods.

Application Areas of Concrete Cutting Wall Saws

- Building structure renovation: suitable for demolishing or renovating concrete walls, floor slabs, beams, and columns, etc., such as reserving space for new doors and windows, elevator shafts, or pipelines.

- Bridge and tunnel engineering: In projects such as bridge demolition, tunnel expansion, and underground passage renovation, accurate concrete structure cutting is achieved to ensure project quality and safety.

- Municipal engineering: used for road cutting, pipeline grooving, foundation renovation, etc., especially in urban infrastructure construction, its high efficiency and environmental protection characteristics are highly favored.

- Nuclear power plant decommissioning and maintenance: precise concrete cutting operations are carried out in high-risk or inaccessible areas to ensure the safety of operators.

- Water conservancy and hydropower engineering are used for cutting and renovation of concrete structures such as dams, canals, and flood control dikes.

Remote-Controlled Wall Saw Price and Purchase Information

YG remote-controlled wall saw has shown strong advantages in improving efficiency, reducing costs, ensuring operational safety, and improving cutting quality. Its concrete wall saw varies depending on the model, configuration, and accessories. The main factors affecting the price include:

- Motor power: The higher the power, the higher the price.

- Maximum cutting depth: Equipment that can cut deeper into concrete is usually more expensive.

- Automation level: Models with more comprehensive functions and higher automation are relatively expensive.

- Accessory configuration: Accessories such as saw blades of different diameters, extended guide rails, and dust collection systems will affect the final price.

As a factory-direct sales, YG promises to provide the most competitive prices and ensure 24-hour online after-sales service and technical support. We recommend that you contact us directly to obtain a detailed quotation based on your specific project needs. Our sales experts will provide you with professional consulting services and help you choose the most suitable equipment model.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()