In the packaging material processing industry, BOPP tape slitting machines are critical equipment for slitting wide BOPP film into narrow tapes, directly impacting product precision, efficiency, and final quality. As an experienced slitter rewinder machine manufacturer, YG understands your needs and is committed to providing you with the most advanced and reliable BOPP tape slitting machines. Whether you’re producing standard sizes or special specifications, our equipment can easily meet your needs. Contact us today for more information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

BOPP Tape Slitting Machine Technical Parameter

| Model | YG- 1300 | YG- 1600 | YG- 1800 |

| Max width | 1300mm | 1600mm | 1800mm |

| Max Diameter for unwinding | ¢1400mm | ¢1400mm | ¢1400mm |

| Minimum width of slitting | 30mm | 30mm | 30mm |

| Max Diameter of rewinding | ¢1000mm | ¢1000mm | ¢1000mm |

| Speed | ≤350m/min | ≤350m/min | ≤350m/min |

| Total Power | 24kw | 26kw | 30kw |

| Power supply | 380V/50hz | 380V/50hz | 380V/50hz |

| Weight | 4000kg | 4500kg | 5500kg |

| Overall dimension(LxWxH) | 3300x3150x1930(mm) | 3300x3450x1930(mm) | 3300x3650x1930(mm) |

Tape Slitting Machine Product Description

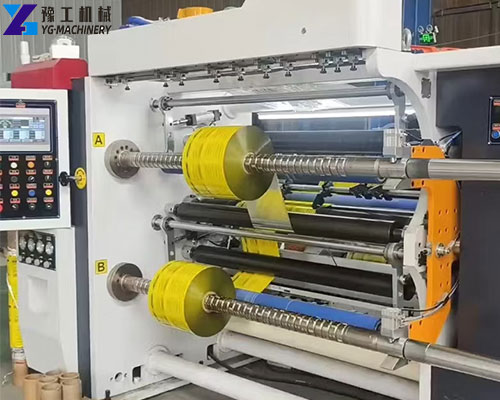

The YG Bopp Tape Slitting Machine features a sturdy steel structure, ensuring stability and durability at high speeds. Its simple and elegant appearance is ergonomically designed, and the user interface is user-friendly and intuitive.

- Structural Components: It primarily consists of an unwinding frame, a web-correcting device, a slitting blade assembly, a rewinding device, a winding device, a tension control system, and a PLC control system.

- Key Components: A high-precision slitting blade shaft, an imported variable-frequency motor, a highly sensitive web-correcting system, and a precise tension control system ensure slitting accuracy and winding uniformity.

- Material and Processing: The machine body is welded from thickened steel plates, with a rust-proof surface treatment and electrostatic spray coating, ensuring long-term use without deformation or rust. Key transmission components are constructed from wear-resistant alloys to ensure the machine’s longevity.

Features and Specifications of the Bopp Tape Slitting Machine

- High-Precision Slitting: Utilizing pneumatic or electric-controlled cutters, the machine achieves precise slitting within ±0.2mm, meeting customers’ precise requirements for narrow tape widths.

- Intelligent Web-Guiding System: Combined with a photoelectric sensor, it monitors the tape edge in real time, ensuring stable material flow and preventing deviation during the slitting process.

- Independent Tension Control: Independent tension control is available for both unwinding and rewinding, ensuring uniform tension throughout the entire process, resulting in a tight, flat roll and no wrinkles or looseness.

- Variable Frequency Drive (VFD) Speed Control: Continuously adjusts machine speed to suit different tape materials and production requirements, optimizing production efficiency.

- Automatic Meter/Counting: Accurate meter or sheet counting facilitates production management and order tracking.

- PLC Touchscreen Control: The machine utilizes a human-machine interface (HMI) touchscreen for intuitive and convenient operation. Multiple sets of process parameters can be stored for quick order changeovers.

- Safety protection device: Equipped with an emergency stop button, safety grating (optional), and multiple protective covers to ensure the safety of operators.

Case Studies and Customer Reviews of YG BOPP Slitting Machines Purchased by Different Customers in Germany and Thailand

Case 1: A German packaging materials company primarily produces BOPP tape for food packaging. The company’s previous slitting equipment had low precision, resulting in frequent burrs on the edges of the tapes, leading to a high rate of customer complaints. In 2023, the company purchased a YG BOPP tape slitting machine.

After using it, the slitting accuracy reached ±0.1mm, the tape edges were smooth and neat, and the customer complaint rate dropped by 90%. Furthermore, the machine’s high speed of 300m/min increased daily output from 800 to 1,200 rolls, meeting the large orders from local supermarkets. The company’s production manager commented, “YG’s equipment has transformed our production. Not only has product quality improved significantly, but efficiency has also increased significantly. Their after-sales service response is also very timely. They are a trustworthy partner.”

Case 2: A Thai tape manufacturer, primarily producing small-sized stationery tapes, previously suffered from insufficient slitting precision, resulting in frequent tape width deviations and significant raw material waste. After introducing YG’s BOPP tape slitting machine in 2024, the slitting pass rate for small-size tapes increased from 85% to 99%, reducing material waste by 60% and saving approximately $8,000 in raw material costs per month.

The factory manager said, “As users of slitting and rewinding machines, we compared many brands and ultimately chose YG. The equipment is easy to operate, and our workers quickly learned how to use it. The quality of the tapes we slit is also very consistent, helping us expand into the local stationery chain market. We are very satisfied!”

BOPP Tape Slitting Machine Manufacturer – YG Machinery

YG’s BOPP tape slitting machines, with their high-precision slitting, high-speed operation, and easy operation, are an ideal choice for BOPP tape manufacturers looking to improve efficiency and quality. Whether boosting production efficiency or enhancing product quality, our equipment delivers tangible value. As a professional slitter rewinder machine manufacturer, we not only provide high-quality equipment but also offer comprehensive technical support and solutions. If you’re looking for an efficient and precise BOPP tape slitting machine, or are interested in equipment like thermal paper slitting machines, and would like specific model specifications and pricing, please contact YG today.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()