Workers in paper processing plants often face the challenge of slitting large paper rolls, over a meter in diameter, into smaller sizes ranging from a few millimeters to over a meter. Traditional equipment is either slow, processing only a few rolls a day, or it produces inaccurate cuts, resulting in some rolls being too wide or too narrow, leaving much paper unusable and wasted. Changing paper sizes also requires lengthy equipment adjustments, significantly delaying production. These issues not only hinder productivity but also increase costs, creating significant headaches for managers. The YG paper slitting machine solves these challenges. It features high-speed slitting, capable of processing hundreds of thousands of rolls a day. It also delivers exceptional accuracy, minimizing error and virtually eliminating waste. Adjusting the cut size is also simple and can be done in minutes, eliminating significant downtime. Whether processing rigid paper for packaging, soft paper for printing, or specialized thermal paper, it can handle it with ease. Contact us for more information on our slitting machines.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Paper Slitting Machine Parameter

| Model | YG-1300 | YG-1600 | YG-1800 |

| Max width | 1300mm | 1600mm | 1800mm |

| Max Diameter for unwinding | ¢1400mm | ¢1400mm | ¢1400mm |

| Minimum width of slitting | 30mm | 30mm | 30mm |

| Max Diameter of rewinding | ¢1000mm | ¢1000mm | ¢1000mm |

| Speed | ≤350m/min | ≤350m/min | ≤350m/min |

| Total Power | 24kw | 26kw | 30kw |

| Power supply | 380V/50hz | 380V/50hz | 380V/50hz |

| Weight | 4000kg | 4500kg | 5500kg |

| Overall dimension(LxWxH) | 3300x3150x1930(mm) | 3300x3450x1930(mm) | 3300x3650x1930(mm) |

6 Features of the YG Paper Slitting Machine

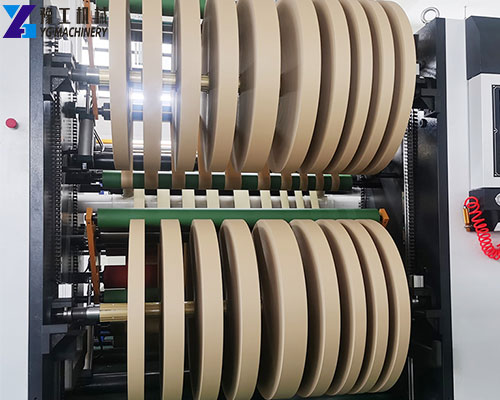

- Precision Slitting Performance: Utilizing high-speed steel circular blades and precision guide rails, the machine achieves a slitting accuracy of ±0.1mm. Even when slitting thermal paper as thin as 0.05mm, it maintains smooth edges, free of burrs and wrinkles, meeting the demands of high-quality paper processing, and is particularly well-suited for thermal paper slitting machine applications.

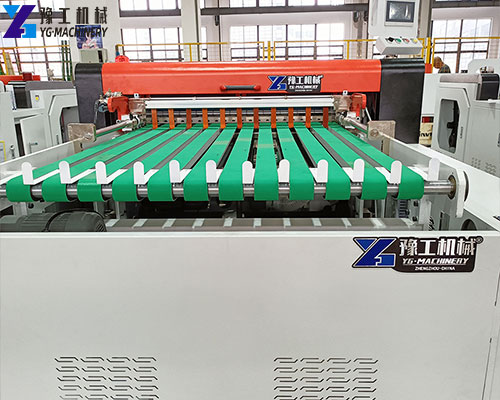

- Efficient Operation: Driven by a servo motor, the machine achieves a maximum slitting speed of 300 m/min, over 50% higher efficiency than traditional equipment. The dual-station rewinding design allows for simultaneous rewinding and roll changing, minimizing downtime. The machine can process up to 144,000 meters of paper rolls in a single 8-hour day, meeting the needs of large-scale production.

- Widely Compatible: It can handle paper weights ranging from 20-300g/㎡, covering a wide range of paper products, including packaging paper, printing paper, thermal paper, and kraft paper. The slitting width is adjustable from 5 to 1200mm, eliminating the need for frequent component replacements and adapting to diverse production needs. It can also be used as a paper roll slitting machine to slit entire rolls of paper.

- Smart and Convenient Operation: The 7-inch touchscreen and PLC control system allow preset parameters such as slitting width, speed, and length. Parameters can be stored (up to 100 recipes) for immediate recall. The machine also features fault alarms (e.g., automatic alarm and shutdown for paper breaks or abnormal tension), simplifying operation and enabling even novice operators to master the process quickly.

- Stable and durable design: The transmission system utilizes imported bearings, resulting in low wear and a service life of over five years. The circular blades in the slitting mechanism feature a micro-adjustable blade clearance, extending tool life (over 300 hours of continuous use after a single sharpening). Shock-absorbing pads are installed on the bottom of the machine to reduce vibration and noise during operation (operating noise ≤ 75 decibels).

- Upgradeable: The machine supports the addition of a dust removal device (to reduce paper dust generated during the slitting process) and an online inspection device (to detect slit size deviations in real time). It can also be integrated with a paper slitter rewinder machine for an integrated slitting and rewinding process, meeting your company’s personalized production needs.

Case Studies and Evaluations of Slitting Machines by Customers from 2 Different Countries

Case 1: Packaging Company in California, USA

- Client Background: A medium-sized packaging company primarily provides carton packaging for local e-commerce companies, processing an average of 500,000 meters of packaging paper per month. Previously, they used traditional slitting equipment, which was inefficient and resulted in high scrap rates.

- Requirement: They needed efficient and precise slitting equipment capable of slitting wide-width packaging paper, reducing downtime, and increasing production.

- Results: After purchasing the YG paper slitting machine, the slitting speed increased from 180 to 300 meters per minute. The dual-station rewinding design reduced daily downtime from 2 hours to 0.5 hours, increasing monthly packaging paper processing capacity to 800,000 meters and reducing scrap rates from 4% to 0.4%, meeting the peak season demand of e-commerce customers.

- Customer Comment: “The YG paper slitting machine has revolutionized our production efficiency. Its precise slitting quality has significantly reduced customer complaints. The machine is easy to operate, easy for employees to use, and provides prompt after-sales service. It is a core piece of equipment in our production line.”

Case 2: Thermal Paper Manufacturer in Tokyo, Japan

- Customer Background: This company specializes in producing thermal paper. Their products are primarily supplied to local retail supermarkets and logistics companies for use in POS machines and express delivery label printing. They need to slit large-format thermal paper into smaller rolls.

- Requirements: They require equipment compatible with thermal paper slitting machines, ensuring high slitting accuracy, a burr-free edge, and protection against damage during the slitting process.

- Results: After using the YG paper slitting machine (customized thermal paper slitting components), we achieved a slitting accuracy of ±0.08mm, resulting in smooth, undamaged thermal paper edges. Our product qualification rate increased from 94% to 99.9%, and our monthly thermal paper processing volume increased by 35%. We successfully secured a long-term partnership with a major local supermarket chain.

- Customer Comment: “YG’s equipment fully meets our high requirements for thermal paper slitting. The accuracy and stability far exceeded our expectations. The machine operates very smoothly, and each roll of paper cut is perfectly aligned. Our product quality has received unanimous praise from our customers. YG’s equipment is truly worth the money!”

Paper Slitting Machine Manufacturer – YG Machinery

For factories struggling with paper slitting, the YG paper slitting machine has proven its effectiveness in numerous practical applications. It overcomes the inefficiency and large errors associated with traditional slitting methods, offering faster, more accurate cutting, helping factories save costs and improve product quality. Many paper mills, both domestic and international, have already chosen this machine and are highly satisfied with it. If your factory needs reliable slitting equipment, don’t hesitate to learn more about the YG paper slitting machine. Contact us to view a hands-on video, inquire about a model that’s right for your factory, or even refer to case studies from other factories. Choosing the right slitting machine early can lead to more efficient and worry-free production, giving your factory a competitive edge in the paper processing industry and helping it meet customer needs more quickly and win more orders. Contact us now.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()