In urban redevelopment and infrastructure upgrade projects, do you often encounter challenges like demolishing a heavy bridge pier, cutting through a reinforced concrete wall tens of meters long, or creating a large new doorway in an existing building? While traditional impact hammers or hydraulic breakers can accomplish these tasks, the resulting noise and vibration are often a major headache. Vibration not only affects the lives of nearby residents but, more seriously, can damage the existing building structure and even cause safety accidents. This high-vibration, high-noise approach is absolutely unacceptable, especially when working near hospitals, schools, or precision factories.

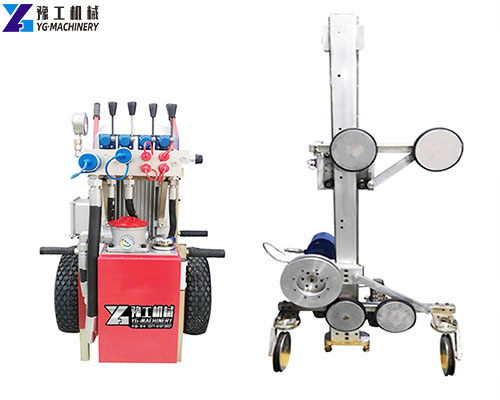

The YG concrete wire saw revolutionizes the traditional “hard-on-hard” demolition method. Our wire saw cutting machine uses a flexible steel cable composed of diamond beads, which grinds the concrete through high-speed circular motion, achieving near-zero vibration and low-noise static cutting. Its cutting depth is limited only by the cable length, allowing for easy and rapid demolition of bridge piers several meters thick or extremely large structures. This technology makes the demolition of complex structures safer and more efficient. Contact us now for more product information.

Concrete Wire Saw Technical Parameter

| Wire Saw Wheel Parameters | Hydraulic Pump Parameters | ||

| Wire Drive Mode | hydraulic | Motor Power | 22/25kw |

| Motor Type | HM-80, 2 Cylinders | Voltage | 220V/380V, 50Hz |

| Minimum Input Power | 25HP/33HP | Hydraulic Pump Type | Gear Pump |

| Output Shaft Speed | 350/940/1300r/min | Main Drive Motor | 40-100L/min |

| Maximum Wire Length | 20m | Working Pressure | 15-20Mpa |

| Feeding Method | Fully hydraulic | Oil Tank Capacity | 17L |

| Wire Saw Wheel Weight | 64kg | Weight | 160kg |

| Motor Weight | 14kg | Size | 700*700*1200mm |

| Size | 1700*700*800mm |

YG Concrete Wire Saw Features & Specifications

- Unlimited Cutting Depth: Unlike traditional circular saws (which have limited cutting depth), the wire saw’s cutting depth is limited only by the rope length, easily handling bridge piers tens of meters thick or ultra-large structures.

- High Precision and Flexibility: Guide wheels can be flexibly installed, enabling cutting at any angle—horizontal, vertical, inclined, and even underwater—with a smooth and flat cut surface.

- Powerful and Stable Power: Utilizing a high-efficiency hydraulic or high-frequency wire saw motor, it provides constant cutting force and speed, maintaining high efficiency even when encountering densely reinforced steel.

- Modular and Lightweight Design: The main body of the equipment can be disassembled into multiple lightweight modules, facilitating transportation and assembly in confined spaces.

- Remote Control and Safety: Equipped with wireless remote control functionality, operators can control the equipment from a safe distance, ensuring construction safety.

Case Studies and Reviews of YG Concrete Wire Saws Used by Customers in Brazil and Malaysia

Case Study 1: Partial Demolition of a Viaduct in Rio de Janeiro, Brazil

- Client Background: A large Brazilian infrastructure company was responsible for the partial structural replacement and demolition of an aging viaduct in downtown Rio de Janeiro.

- Problem Solved: Located in a busy downtown area, the viaduct had extremely high requirements for noise and vibration control, and traditional impact hammers and blasting methods were strictly prohibited.

- Product Used: YG hydraulic diamond wire saw machine.

- Results: The client used the concrete wire saw to precisely and statically cut the piers and beams to be demolished. The noise level during construction was far below regulatory standards, and no vibration was generated. The cut structural blocks could be directly hoisted, greatly accelerating the demolition process.

- Customer Testimonial: “YG’s wire saw cutting machine solved our biggest challenge in our downtown construction project. Its cutting precision is high, and it’s completely vibration-free, with no impact on surrounding residents or buildings. This equipment is irreplaceable in urban redevelopment.”

Case Study 2: Dam Spillway Renovation in Malaysia

- Client Background: A Malaysian water conservancy engineering company needed to renovate and open the thick reinforced concrete structure of the spillway gate of a large dam.

- Problem Solved: Concrete thickness exceeding 4 meters with extremely high reinforcement density; traditional cutting tools were extremely inefficient.

- Product Used: YG high-frequency wire saw.

- Results: Utilizing the constant power output and high linear speed of the high-frequency wire saw, the machine overcame the challenges of ultra-thick concrete and dense reinforcement, completing the cutting operation efficiently and at a stable speed. The high-frequency motor ensured stable power output, and the cutting efficiency increased by 25% compared to expectations.

- Customer review: “The power and stability of this wire saw machine are impressive. It performed very reliably when cutting a 4-meter-thick dam structure, producing a very smooth cut, which saved us time in the subsequent installation work.”

Safety Guidelines for High-Frequency Wire Saw Cutting Operations at Heights and in Confined Spaces

- Remote control: Operators control the cutting from the ground or a safe area, eliminating the need for personnel to approach high-altitude or enclosed hazardous areas.

- Vibration-free cutting: Utilizing static grinding, it eliminates impact and vibration, removing the risk of falling objects and secondary structural damage.

Specific safety measures:

- At heights: The lightweight, modular design of the equipment facilitates installation; cut concrete blocks must be securely fixed before precise hoisting to prevent falls.

- Confined spaces: Remote operation avoids personnel entering toxic or oxygen-deficient environments; wet cutting suppresses dust, protecting air quality; the compact size of the equipment reduces worker exposure time to hazardous environments.

Concrete Wire Saw for Sale – YG Machinery Manufacturer

For any contractor seeking to maximize efficiency, the value of a YG concrete wire saw far exceeds its purchase price. Traditional demolition methods, such as large pneumatic drills or hydraulic breakers, not only require significant manpower and generate substantial noise pollution but also cause structural damage due to vibration, leading to additional repair costs and lengthy construction periods. The diamond wire saw machine, however, represents a revolution in efficiency and cost.

Firstly, in terms of efficiency, the high-frequency wire saw’s cutting speed far surpasses traditional tools, significantly shortening the construction period. This means contractors can complete projects faster, freeing up manpower and capital for the next project, accelerating cash flow. Secondly, in terms of cost, the wire saw machine is remotely controlled, greatly reducing the need for on-site operators and saving on high labor costs and complex safety protection costs. Most importantly, vibration-free static cutting ensures the safety of surrounding structures, eliminating the huge repair costs caused by vibration damage. This comprehensive saving in time, labor, and structural risk makes the YG concrete wire saw a high-value asset with an extremely short return on investment cycle.

Contact YG’s professional technical team now. Simply provide your engineering drawings and cutting requirements, and YG’s experts will develop the most suitable wire saw cutting machine solution for you, along with a detailed quote and installation instructions.

![]()