In the rapidly evolving construction market, time is a hard cost. Large industrial plants, logistics parks, and airport hangars often require the completion of tens or even hundreds of thousands of square meters of ground construction within extremely short timeframes. Continuing to rely on traditional, labor-intensive ground leveling methods will not only slow down the overall project schedule but also cause costs to skyrocket due to the large amount of manual labor and repetitive leveling work. For contractors hoping to stand out in the fierce market competition, finding equipment that can significantly increase productivity and reduce reliance on manual labor has become crucial for achieving high profit returns.

The YG concrete floor leveling machine, employing advanced automatic concrete leveling technology, enables wide-area, continuous, and rapid operation. A single machine can easily level more than five times the area of a traditional manual team per day, compressing work that would normally take weeks into just a few days. This means you can enter the subsequent construction phases earlier, achieving project delivery ahead of schedule, thus earning owner rewards and enhancing your company’s reputation. Furthermore, its high degree of automation significantly reduces reliance on highly skilled workers, thereby substantially lowering long-term labor costs for the project. Contact us now for more product information to ensure you stay ahead of the market in any large-scale ground project.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Concrete Floor Leveling Machine Parameter

| Model | YGJX31 | YGJX32 | YGJX33 | YGJX34 |

| Engine | ||||

| Model | Generator set | GX390 Electric start | GX390 Electric start | GX390 Electric start |

| Power | 2.0kW | 13hp/3600rpm | 13hp/3600rpm | 13hp/3600rpm |

| Fuel tank (L) | 14.5 | 6.5 | 6.5 | 6.5 |

| Running device | ||||

| Drive | Motor | Hydraulic motor | Hydraulic motor | Hydraulic motor |

| Running mode | Infinitely variable speed | Handle control, stepless speed | Handle control, stepless speed | Handle control, stepless speed |

| Running speed(m/min) | 0-36 | 0-45 | 0-65 | 0-45 |

| Suggest working speed(m/min) | 5 | 5 | 5 | 5 |

| Screed head | ||||

| Type | Self-leveling | Electric control, self-leveling | Self-leveling | Hydraulic control, self-leveling |

| Width | 2500mm | 2500mm | 2500mm | 2500mm |

| Exciting force | 500N | 500N | 500N | 500N |

| Vibration frequency | 50Hz | 50Hz | 50Hz | 50Hz |

| Laser control system | ||||

| Control type | Microcomputer laser scan | Microcomputer laser scan | Microcomputer laser scan | Microcomputer control |

| Operation mode | Walk-behind | Walk-behind | Walk-behind | Walk-behind |

| Forward and reverse | Handgrip control, stepless speed-walking | Hydraulic control | Handgrip control, stepless speed-walking | Hydraulic control |

| Size and weight | ||||

| Working size(mm) | 2758*2622*1980 | 2740×2659×1980 | 2578×2643×1980 | 2780*2622*1980 |

| Weight(kg) | 295 | 365 | 380 | 410 |

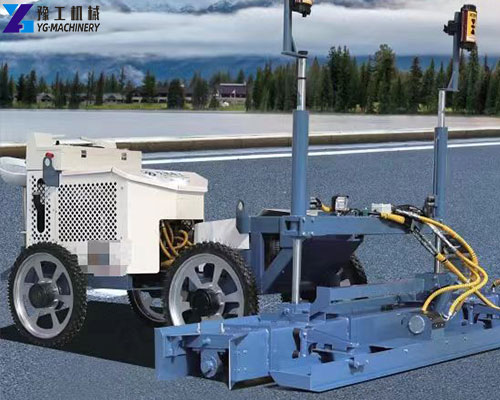

Core Structural Components of a Laser Screed Machine

- Frame and Chassis: A robust steel frame ensures the machine’s stability and durability in complex construction environments. Larger machines typically employ four-wheel or tracked drive for easy mobility.

- Laser Emitter and Receiver: The laser emitter (usually placed at a fixed point on the site) establishes a horizontal reference plane. The laser receiver on the machine captures the signal in real time and transmits it to the control system.

- Screed Head and Blade: The core working component of the screed machine. The blade is responsible for scraping excess concrete to the laser reference height.

- High-Frequency Vibration System: Located behind the leveling head, it provides high-frequency vibration to the concrete during scraping, achieving rapid compaction.

Advantages of the YG Concrete Floor Leveling Machine:

- Significantly Improved Floor Quality: Eliminates errors from manual leveling, resulting in high floor flatness, longer service life, and reduced maintenance costs.

- Reduced Labor Dependence and Costs: The automatic concrete leveling machine‘s characteristics minimize reliance on manual skills, significantly reducing the number of on-site workers and their workload.

- Accelerated Construction Progress: Extremely high operating efficiency allows large-scale concrete flooring to be completed in a short time, shortening the overall project duration and enabling earlier delivery.

- Saving Concrete Materials: The high-precision leveling system ensures accurate concrete usage, avoiding concrete waste caused by errors in manual leveling.

- Meeting Functional Floor Requirements: Meets the needs of locations with extremely stringent requirements for floor flatness, such as automated warehouses and electronics factories.

USA and Canadian Clients Use YG Laser Leveling Machines to Complete Projects

Case Study 1: Large-Scale Logistics Center Project in Texas, USA

- Client Background: A well-known logistics real estate developer in the United States needed to build a 100,000 m² ultra-flat floor logistics center in Texas, requiring a surface flatness meeting FM standards.

- Problem Solved: Traditional methods could not achieve the required flatness, and the construction period was extremely tight.

- Product Used: YG large-scale self-propelled automatic concrete leveling machine (leveling width 6.0m).

- Results: Using YG’s concrete floor leveling machine, the client increased the daily paving area to 4,000 m² and shortened the overall construction period by 35%. The final surface flatness far exceeded the client’s expectations, successfully passing third-party FM certification.

- Customer Testimonial: “YG’s concrete laser leveling machine solved our world-class challenge of achieving ultra-flat surfaces over large areas. Its precision and speed completely changed our understanding of floor construction.”

Case Study 2: Vancouver Electronics Factory Project, Canada

- Client Background: A high-tech electronics manufacturing company in Canada required its new factory floor to achieve an ultra-high precision of 1 mm to ensure the installation and operation of precision equipment.

- Problem Solved: Stringent precision requirements for the floor, coupled with the need to minimize construction noise.

- Product Used: YG small, handheld laser concrete leveling machine.

- Results: Leveraging the flexibility and high-precision control of the small machine, the client achieved near-perfect floor flatness within a confined equipment installation area. Simultaneously, the machine operated quietly and efficiently, without disrupting normal production in adjacent workshops.

- Customer Testimonial: “We are extremely particular about precision. The performance of this YG concrete floor leveling machine was amazing; it delivered a floor that exceeded our required standards, ensuring the perfect installation of our new equipment.”

Efficient Collaboration Between Concrete Floor Leveling Machine and Road Marking Machine in Logistics Park and Parking Lot Projects

Concrete floor leveling machines and road marking machines have achieved a perfect balance of quality and efficiency in ground construction processes during collaboration in large parking lot and logistics park projects.

Firstly, the concrete laser screed machine undertakes the most critical foundational task. Utilizing laser-guided technology, it rapidly lays out concrete surfaces with millimeter-level flatness and high density. In logistics parks, this ultra-flat surface is crucial for ensuring the safe and stable operation of automated equipment (such as unmanned forklifts); in parking lots, it provides the accuracy of drainage and parking space placement.

【High-Efficiency Collaboration Mechanism】 Because the leveling machine provides a smooth, robust, and error-free foundation, it creates ideal conditions for subsequent marking operations. The road marking machine can begin work immediately after the concrete has cured:

- Improved Accuracy: The flat surface reduces visual errors and measurement difficulties during marking, ensuring the accuracy of parking lines and traffic signs.

- Extended Lifespan: Marking paint adheres better to a smooth, dense surface and is less prone to wear or peeling, thus extending the lifespan of the markings and reducing maintenance costs.

- Time Optimization: The high efficiency of the leveling machine allows the site to enter the marking phase more quickly, accelerating the overall project delivery speed.

This combined approach of “high-precision leveling” and “efficient marking” represents best practice in modern engineering for improving quality, saving costs, and accelerating project cycles.

Concrete Floor Leveling Machine Manufacturer – YG Machinery

In the fiercely competitive construction industry, any investment must yield significant economic benefits. The core value of the YG concrete floor leveling machine lies in its breakthroughs in both efficiency and quality, creating entirely new profit models for you. Traditional floor leveling requires substantial labor, is time-consuming, and has a high rework rate, resulting in significant hidden costs. YG’s automatic concrete leveling machine, with its 500% efficiency improvement, directly shortens the construction period to the extreme, significantly saving labor and time costs. More importantly, laser-level precision effectively avoids concrete material waste and subsequent repair costs caused by ground errors. In projects requiring functional floor marking (such as using road marking machines), a highly level ground also reduces the amount of marking material used and extends the lifespan of the markings. The high-precision floor quality delivered by this concrete laser leveling machine allows your projects to pass the most stringent acceptance standards, earning your company a high-standard reputation and securing more high-value orders. This comprehensive advantage of high efficiency, low waste, and high standards ensures that your investment in the concrete floor leveling machine will yield a substantial return in a very short time. Don’t let inefficient manual leveling eat into your profits! Contact us now for more product information and pricing, and invest in this laser concrete leveling machine for your next project to achieve cost savings and maximize profits.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()