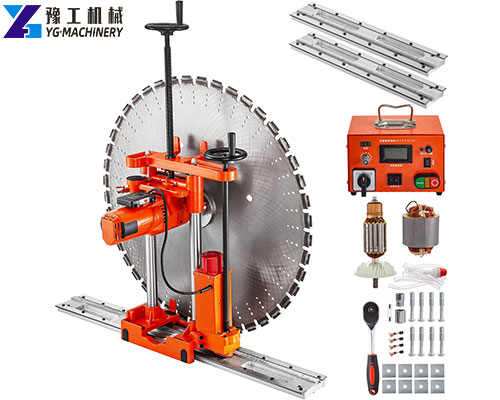

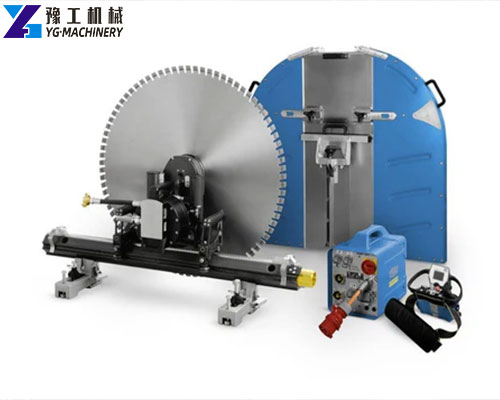

In the construction and renovation of modern buildings, bridges, tunnels, and various infrastructures, accurate and efficient cutting of concrete walls is a common demand. Whether it is opening door and window openings, removing structural parts, or repairing and reinforcing, traditional crushing or manual chiseling methods are often inefficient, noisy, and dusty, and it is difficult to ensure the cutting accuracy and structural integrity. YG Machinery’s electric wall saw is professional equipment dedicated to cutting hard walls such as concrete, brick walls, and stone. It is mainly composed of a high-power electric motor, a high-strength guide rail system, a diamond saw blade, a control box, and an auxiliary cooling/dust removal system. The whole machine is compactly designed and highly modularized, making it easy to transport and assemble on site. The operator can operate remotely through the control panel or remote control (some models), which greatly improves the safety of construction. Contact us for more product information.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Parameters of Hot-sale Electric Concrete Wall Saw:

| Electric Type Wall Saw Machine | |||

| Model | YG-800 | YG-1000 | YG-1200 |

| Type | Manual type / Semi-automatic type / Full automatic type (every model has three types) | ||

| Cutting depth | 320mm | 420mm | 520mm |

| Saw blade diameter | 800mm | 1000mm | 1200mm |

| Power/Voltage | 7280w/220v | 7580w/220v | 7880w/220v |

| Rotary speed | 400r/min | 380r/min | 350r/min |

| Machine weight | 35kg | 38kg | 45kg |

| Machine size | 55*55*78cm | 55*55*88cm | 55*55*98cm |

Remark:

|

|||

Working Principle: Simple and Efficient Electric Wall Saw Machine

The working principle of the YG electric wall saw machine is relatively intuitive: First, the high-strength guide rail is firmly installed on the surface of the wall to be cut along the preset cutting line. Then, the cutting head with a diamond saw blade is installed on the guide rail. After starting the motor, the saw blade starts to rotate at high speed. The operator controls the cutting head to move slowly along the guide rail through the control system. The rotating saw blade relies on the high hardness of the diamond blade to gradually grind and cut the concrete material. By adjusting the cutting depth multiple times, the wall is finally completely cut off. The guide rail ensures the straightness and stability of the cutting, and the diamond saw blade ensures the efficiency of the cutting and the adaptability to hard materials.

Features of Electric Wall Saws:

- Powerful power output: Equipped with high-performance motors, it provides stable and reliable cutting power and can easily cope with concrete walls of various strength levels.

- Precise guide rail system: High-precision guide rails are used to ensure that the cutting line is straight and the edges are neat, without the need for a lot of later repairs.

- Adjustable cutting depth: According to construction requirements, the cutting depth of the saw blade can be adjusted quickly and easily to meet the cutting requirements of walls of different thicknesses.

- Compatible with multiple saw blades: It supports the installation of diamond saw blades of different diameters, with a maximum cutting depth of hundreds of millimeters and a wide range of applications.

- Perfect safety protection: Multiple safety mechanisms, such as integrated overload protection and leakage protection, ensure the safety of equipment and operators.

- Efficient cooling/dust removal: Optional water cooling system for wet cutting, or dry cutting with professional dust collection equipment (that is, used as a dry concrete wall saw to effectively reduce dust pollution).

- Remote control function: Some high-end models provide a wireless remote control function, and operators can control from a safe distance to further improve safety.

- Modular design: The main components can be quickly assembled and disassembled, which is convenient for transportation, handling, and on-site installation, especially suitable for areas with limited space.

Two Customer Electric Concrete Wall Saw Cases and Comments from the International Market:

Case 1: California, USA | Large Commercial Building Renovation Project

- Customer Background: An American contractor specializing in commercial building renovation.

- Usage Problem: A large number of new door and window openings need to be cut quickly and accurately on the concrete shear walls of multiple existing buildings. The cutting accuracy and efficiency are extremely high, and it is hoped that the dust on site will be minimized.

- Solution and Effect: They purchased several YG high-power electric wall saws, equipped with corresponding guide rail systems and industrial-grade dust collection equipment, and operated as dry concrete wall saws. The equipment runs stably, the cutting speed is far beyond expectations, and the cutting surface is smooth and flat, with almost no need for post-finishing. More importantly, with the dust collection system, the dust on the construction site is effectively controlled, meeting strict environmental protection requirements.

- Customer review: “YG’s electric wall saw is amazing! It is not only powerful and has high cutting accuracy, but also has excellent dust removal when used as a dry cutting device. This helped us complete the project on time or even ahead of schedule, and the customer was very satisfied. Highly recommended!”

Case 2:Berlin, Germany | Subway Station Upgrade and Reconstruction Project

- Customer background: An engineering company responsible for the maintenance and upgrading of urban rail transit infrastructure.

- Usage problem: The concrete structure renovation in the operating subway station requires the removal of some walls and floor slabs. The construction space is narrow and extremely safe to avoid interference with subway operations.

- Solution and effect: They chose a compact electric wall saw from YG, which is easy to install in a small space with its modular design. The stable cutting and low vibration characteristics of the equipment minimize the impact on surrounding structures. The remote control function allows operators to operate in a safe area.

- Customer review: “In such a complex construction environment, safety and reliability are the top priorities. YG’s electric wall saw performed very well, with easy operation, smooth cutting process, and acceptable noise and vibration. Our engineers and workers spoke highly of this equipment.”

Electric Concrete Wall Saw Price – YG Machinery

In summary, YG Machinery’s electric concrete wall saw has become an ideal choice in the field of modern concrete cutting with its powerful performance, precise cutting, reliable safety performance, and wide range of applications. Whether you are facing building renovation, structural demolition, or infrastructure construction, the YG wall saw machine can provide you with efficient, precise, and safe solutions to help you improve project quality and reduce operating costs. If you are looking for a high-performance concrete wall cutting saw or want to know which model of dry concrete wall saw for sale is best for your project needs, please don’t hesitate! Contact us now to get your exclusive electric wall saw solution and detailed quotation!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()