The rebar derusting machine is a steel bar rust removal device, which can be called rebar rust remover, steel bar derusting machine, rust removal machine, and removes rust from steel, etc. The rebar derusting machine is mainly used to polish the surface of old steel bars or rusty steel bars in the rainy season. Contact us to learn more.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

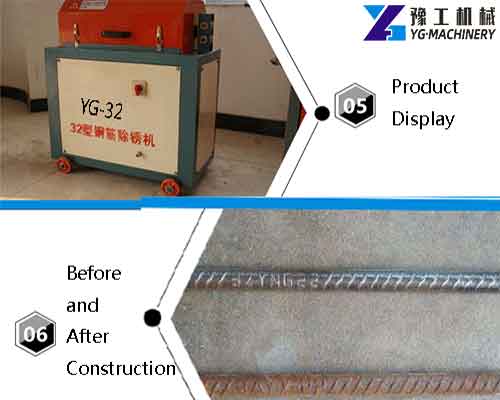

Rebar Derusting Machine Parameter:

| Model | YG-32 | YG-51 |

| Working Range | 14-32mm | 48/51mm(without traction wheel)|32-51mm(with traction wheel) |

| Working Speed | 580-600r/min | 580-600r/min |

| Power | 2.2kw*2 (without traction wheel)|3kw*2(with traction wheel) | 3kw*2 |

| Motor | 380V | 380V |

| Weight | 160kg | 220kg |

| Dimensions | 800*500*600mm | 800*500*800mm |

Principle of Operation:

The steel bar derusting machine is driven by the power switch to run the two motors forward and reverse, and the double descaling assembly is driven to rotate by the V-belt to achieve the derusting effect.

Rebar Rust Remover Machine Working Principle:

The working principle of the steel bar derusting machine is two rows of steel wire rods/wire wheels(wire wheels for non-polishing machines). The two angles rotate at high speed to remove the rust. The rebar passes quickly in the middle fast.

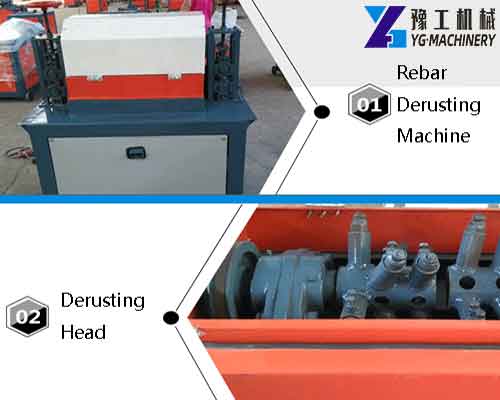

Composition:

The machine consists of 2 electric motors, a double rust removal assembly, double Vientiane bearings, bearing housings, incoming and outgoing tugs, traction handles, etc. It has the advantages of small size, low price, and convenient movement.

Advantages of Rebar Derusting Machine:

The rust removal speed is fast, the effect is good, and the cost of rust removal is low. While removing rust, it can also remove burrs and debris on the surface, which has a certain beautifying effect on the surface. High controllability. Especially for large steel plates, steel bars, steel, steel structure descaling, suitable for large amounts, heavy rust, and steel with fasteners.

Rebar Derusting Machine Use:

It has a good derusting effect and performance for rebar and is used for derusting the surface of the rebar. It can quickly remove the oxide scale layer and surface rust stains and residual oil stains of the steel bar due to rain, and restore the original color of the steel bar after cleaning, with strong stability and significantly improved corrosion resistance.

Rebar Rust Remover Features:

A new machine carefully researched the needs of customers to remove rust. Derusting and polishing the 14-32 steel bars saves the labor of polishing and greatly saves manpower.

Three Steps in Using Steel Bar Rust Remover and Steel Bar Rust Remover:

First: Connect the power supply(380V), install the leakage protection device to the ground, turn on the power switch, and run for 2 minutes to see if it is normal.

Second: Steel bar correction, the single wire adjustment part of the two rust removal devices must be close to the steel bar to be corrected. During the calibration process, a steel bar 3mm smaller than the steel bar to be rusted can be pre-selected to correct the feed inlet, two rust removal devices ( wire brush) adjustment parts, and the outlet. ( For example, the steel bar for rust removal 25 can be corrected by the steel bar 22). our factory is calibrated based on 22-round steel. Customers can adjust the rust removal device according to different steel bar models. Adjust the lock nut.

Third: Precautions for safe operation:

- Check whether the fixing bolt of the wire brush is loose, the transmission part is lubricated, and the closed protective cover and dust exhaust equipment are in good condition.

- The operator must tighten the cuffs tightly with dust masks, gloves, and protective glasses.

- It is strictly forbidden to remove the rust on the steel bar formed by the hook. Steel bars with excessive curvature should be de-rusted after basic straightening.

- During the operation, the steel bar should be laid flat, held tightly, and fed sideways. It is strictly forbidden to stand in front of the descaler. The rust removal of the entire long steel bar should be operated by two people in cooperation with each other.

Rebar Derusting Machine Operation Process:

- When in use, place the rebar rust remover on a solid, level surface, and place the carrier in the required length for the material.

- According to the diameter of the material, adjust the transmission of the inlet and outlet to the center of the shaft. It is advisable to feed in and out a material freely. Lubricate each rotating part of the machine.

- Adjust the steel brush wheel to be 5-8mm smaller than the diameter of the raw material, so the steel wheel is symmetrical.

- Put the raw materials neatly on the side of the feed inlet and clean up the site on the side of the discharge.

- Connect the motor power supply according to the motor requirements. The motor power supply should be fastened to the electrical control box with the specified cable.

- The motor must rotate according to the marked arrow, synchronize with the feeding port, feed after starting, and enter normal production.

Precautions:

- The height of the raw material bracket must be consistent with the import and export.

- Raw materials must be straight.

- The feeding and discharging drive must be adjusted to be smaller than the diameter of the raw material.

- The power supply must match the click requirements and be grounded.

- Every 5 hours of work, check and refuel the transmission bearings.

Rebar Derusting Machine for Sale in YG Machinery

We also have other steel machinery, rebar straightening and cutting machines, rebar threading machines, steel bar cutting machines, rebar bending machines, rebar couplers, beam bending machines, steel hoop bending machines, hydraulic punching and shearing machines, rebar upsetting machines, pipe shrinking machines, reinforced cage winding machines, stirrup bending machines, chain link fence machines, etc. If you are interested in this machine, please don’t hesitate to contact us.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800