Parameter of Cat Litter Pellet Making Machine:

| Model | Capacity(TPH) | Main Motor Power(KW) | Feeder Motor Power(KW) | Conditioner Power(KW) | Dia. of Ring Die(mm) | Final Pellet(mm) |

| YG250 | 1-2 | 22 | 0.75 | 1.5 | 250 | 2~12 |

| YG320 | 3-4 | 37 | 1.5 | 2.2 | 320 | 2~12 |

| YG350 | 5-7 | 55 | 1.5 | 3 | 350 | 2~12 |

| YG420 | 8-12 | 110 | 1.5 | 7.5 | 420 | 2~12 |

| YG508 | 10-18 | 160 | 2.2 | 11 | 508 | 2~12 |

| YG558 | 15-25 | 180/200 | 2.2 | 11 | 558 | 2~12 |

| YG558D | 14-22 | 160/180/200 | 1.5 | 7.5 | 558 | 2~18 |

| YG678 | 20-30 | 220/250 | 2.2 | 11 | 678 | 2~12 |

| YG678D | 15-25 | 200/220/250 | 2.2 | 11 | 673 | 2~18 |

| YG768 | 25-40 | 280/315 | 2.2 | 11 | 768 | 2~12 |

| YG858 | 25-42 | 280/315 | 2.2 | 15 | 858 | 2~18 |

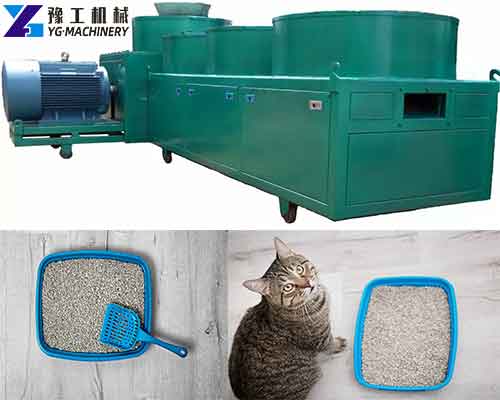

How To Make Paper Cat Litter Pellets?

YG Machinery cat litter pellet production line can be established for users according to different raw materials. Wood cat litter pellet production line, paper cat litter pellet production line, bentonite cat litter pellet production line, silica gel pellet cat litter Production Line, and tofu cat litter pellet production line.

- Collecting. Waste papers are abundant in schools, printing companies, markets, and office buildings. Paper mill residues are another important source. These materials have different sizes and features, you need to sort them into groups for future processing.

- Grinding. You need a hammer mill to crush large sizes of waste papers into powder with a size of less than 6mm.

- Drying. The moisture content of paper materials should be 12%-15%. Neither higher nor lower are not acceptable. If the papers are too dry, it would cause a static charge and make the pellets light and fluffy. In this regard, you can add a certain amount of water to the pellet-making machine when processing. If the moisture content is over-high, you need to lower it by putting the powdery material in a rotary dryer or a pipeline dryer.

- Making paper cat litter pellets. This is the core process of making paper pellets. Feed materials of proper size and moisture content into the paper pellet machine. They will get compressed and molded in the compression chamber and come out in the shape of cylinders. Usually, there are ring die pellet machines for large-scale production and flat die pellet machine for small-scale production.

- Pellet cooling. The newly produced paper pellets have a high temperature of 90 ℃. So you need a pellet cooler to lower the pellets to room temperature. Cooling can improve the stability and hardness of paper pellets. Also, you can put the paper pellets in the open air for natural withering.

- Pellet sieving. Use a sieve to remove the residual powders in the paper pellets. These powders can be re-pelletized together with the left materials.

- Pellet packing. A Pellet packer is essential for large-scale paper pellet production. It can weigh and package the pellet products in bags. The package can protect the paper pellets from erosion by moisture and wind. Pellets can be stored in closed silos.

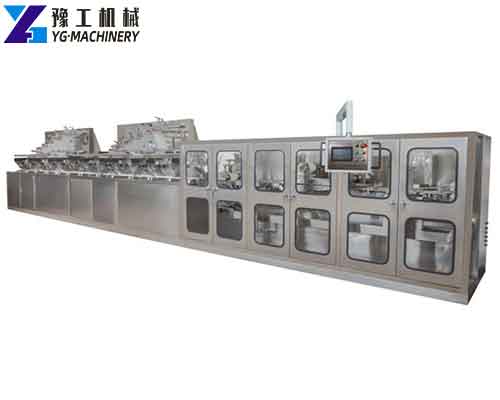

Composition of Cat Litter Pellet Production Line:

A complete cat litter production plant consists of cleaning machines, hammer mills, mixers, ring die granulators, coolers, microwave dryers, screening machines, packaging machines, and other auxiliary equipment. Based on thousands of successful tofu cat litter line projects, YG Machinery can provide you with the most ideal and suitable cat litter plant project plan. We can customize cat litter handling lines according to your requirements for particle size, hourly capacity, and different animals. There are experienced engineers for overseas installation and training.

Cat Litter Production Line Price – YG Machinery Manufacturer

What’s the cat litter pellet machine price? Because different customers have different requirements for pellets, there will be many differences in the details of our pellet machine design. Therefore, the actual cat litter pellet maker machine prices for different projects are different. Even if the customer wants to produce the same type of pellets, if the customer’s raw materials and production technology are different, the cat litter pelletizer machine ring dies, conditioner, etc. will be different.

In addition, we also have wet wipe machines, tissue-making machines, slitting machines, disposable cup-making machines, plastic thermoforming machines, paper bag-making machines, garbage bag-making machines, cast film machines, woven bag-making machines, disposable slipper machines, shoe cover-making machines, surgical cap making machines, etc. Contact us if you want to know more!